Introduction of the productSteel Mining Rods can be customized to meet the unique requirements of different mining processes. With options to adjust length, diameter, and hardness, these rods offer flexibility to optimize performance for both coarse and fine grinding.

Contact Now

Introduction of the productSteel Mining Grinding Rods can be customized to suit the specific needs of different mining processes. With adjustable lengths, diameters, and hardness, these rods provide flexibility to optimize grinding efficiency for both coarse and fine grinding.

Contact Now

Introduction of the productThe primary advantage of our Mining Grinding Rods is their exceptional durability. Manufactured using advanced processing techniques, these rods are designed to withstand high impact and continuous grinding without breaking or deforming. Their high wear resistance ensures that they maintain consistent performance throughout their service life, reducing the frequency of replacements and minimizing downtime in mining operations.

Contact Now

Low Breakage Rate for Enhanced Production EfficiencyThe breakage rate is a key indicator of the quality of Grinding Rods For Mining . Utilizing advanced manufacturing techniques and carefully selected materials, our grinding rods achieve an exceptionally low breakage rate, typically maintained at ≤1%. This ensures durability during prolonged grinding operations, minimizing the need for frequent replacements and maintenance.

Contact Now

Introduction of the productThe Grinding Steel Rods For Sand / Iron / Coal Grinding deliver exceptional grinding efficiency, thanks to their uniform hardness and smooth surface. These rods facilitate more effective material breakdown, leading to improved particle size distribution and better throughput. Whether used in wet or dry grinding, the design of the rods ensures optimal contact with the material, enhancing grinding performance.

Contact Now

Introduction of the productBuilt to endure the harshest mining conditions, Steel Grinding Mining Rods are engineered for superior durability and resistance to high-impact forces. These rods are designed to withstand the demands of heavy-duty grinding while maintaining their structural integrity.

Contact Now

Introduction of the productThe accuracy of the length and diameter of Grinding Rods directly impacts their performance in grinding operations. By rigorously controlling each step of the production process, we ensure that every rod meets the required dimensional standards. This ensures that the grinding media in rod mills are evenly distributed, reducing wear and improving operational efficiency.

Contact Now

Introduction of the productDurability is a hallmark of Mining Grinding Steel Rods, crafted to withstand the challenging conditions of mining environments. Made from high-quality materials, these rods exhibit excellent wear resistance, minimizing breakage risks and extending service life.

Contact Now

Introduction of the productBuilt to endure the toughest mining conditions, Mining Steel Rods are known for their exceptional durability and strength. These rods are designed to withstand high-impact forces and heavy grinding loads.

Contact Now

Introduction of the productSteel Grinding Rods For Mining are crafted with high precision, ensuring uniform diameter and length, which is critical for maintaining consistent grinding performance. Their accurate sizing promotes smoother material breakdown and minimizes the risk of breakage or uneven wear.

Contact Now

Introduction of the productBuilt for durability, Steel Grinding Rods deliver long-lasting performance even under harsh grinding conditions. Their robust construction minimizes wear and breakage, reducing downtime and maintenance costs.

Contact Now

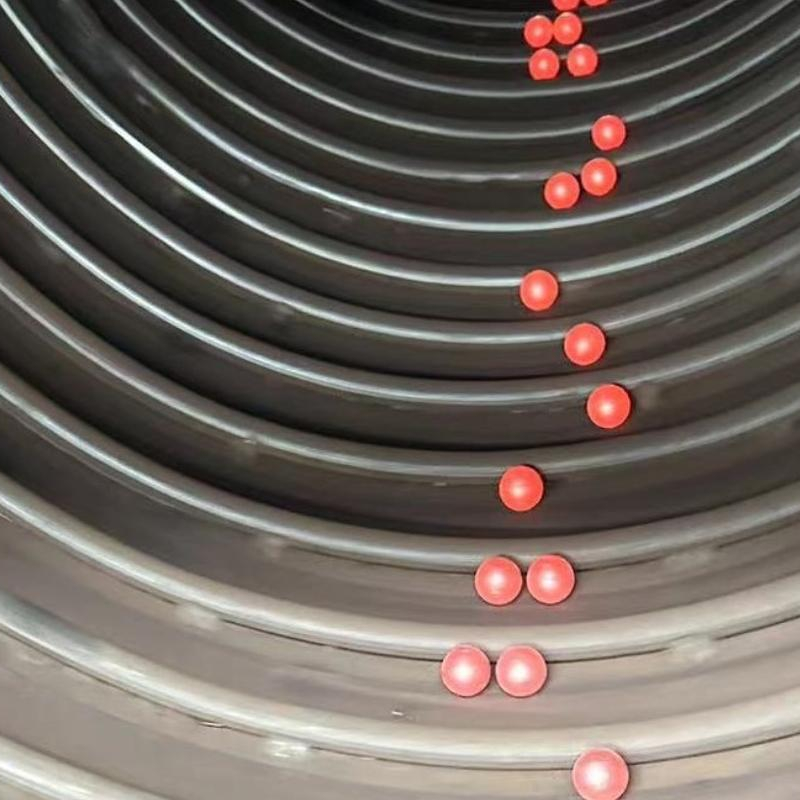

Introduction of the productThe grinding steel rods are a type of grinding media that is added in rod mills. Their function is to break, crash, impact and abrase the minerals ores and other materials in same size.

Contact Now

Introduction of the productMade from high-quality steel, Mining Steel Grinding Rods are built to withstand the most demanding mining conditions. They are highly durable, resistant to wear, and perform well under heavy loads and high-impact grinding.

Contact Now

Introduction of the productHigh carbon forged steel balls are formed through the forging process, which results in a more uniform and dense internal metal structure, significantly enhancing the ball’s strength and compressive resistance.

Contact Now

Introduction of the productThe Hot Rolled/Forged Grinding Ball for Copper, Gold, Iron, Silver is specifically designed to enhance grinding efficiency and optimize metal recovery in milling operations. These balls provide excellent energy transfer during the grinding process, improving material breakdown and ensuring better throughput. The uniformity of the ball size and hardness helps to minimize friction and reduce energy consumption, contributing to smoother operations.

Contact Now

Introduction of the productDesigned to withstand harsh mining conditions, Grinding Steel Rods For Mining are made with high-quality materials that offer excellent durability and wear resistance. Their toughness ensures they perform effectively even under high-impact and abrasive environments. By reducing breakage rates and maintaining consistent performance, these rods help to improve operational efficiency and minimize downtime.

Contact Now

Introduction of the productBuilt to withstand the toughest mining environments, Mining Grinding Steel Rod offer exceptional durability under extreme conditions. These rods are engineered to handle heavy loads and high-impact grinding without losing their structural integrity.

Contact Now

Introduction of the productThe consistent quality and uniform hardness of Casting Chrome Mining Ball ensure high grinding efficiency. Their optimized structure allows for more efficient material breakdown, which translates into better throughput and energy utilization in grinding mills. The reliable performance of these balls in demanding environments contributes to a consistent grinding process, allowing for increased productivity.

Contact Now

Introduction of the productThe Wet and Dry Grinding Ball Cr(1-32%) offers exceptional wear resistance, ensuring longer life and reduced downtime. The higher chromium balls (32%) are specifically engineered to withstand abrasive conditions, delivering superior hardness and corrosion resistance. This results in less frequent replacements and improved grinding efficiency.

Contact Now

Introduction of the productThe High and Super High Chromium Cast Grinding Ball is designed to maximize grinding efficiency by offering consistent performance and reliable results. The uniform hardness and smooth surface finish of these balls ensure optimal grinding performance with minimal energy consumption. Their ability to maintain their shape and size throughout the grinding process improves grinding efficiency, resulting in finer material particle size and higher throughput.

Contact Now

Introduction of the productThese 1/2.5/3/3.5/4 Inch Grinding Balls are manufactured with high-quality materials to ensure exceptional durability and performance. Their uniform hardness and smooth surface allow for consistent and efficient energy transfer, maximizing grinding performance while minimizing energy consumption. Built to withstand heavy impact and abrasive forces, these grinding balls offer extended service life, reducing the need for frequent replacements and minimizing downtime in milling operations.

Contact Now

Introduction of the productMade from high-quality alloy materials, Cast Grinding Cylpebs are engineered to offer superior wear resistance, making them ideal for high-demand grinding applications. The alloy composition provides excellent hardness and resistance to abrasive forces, which allows them to maintain their shape and performance over extended use.

Contact Now

Introduction of the productThe Grinding Cast Ball for Copper, Gold, Iron, Lithium is engineered for durability, featuring excellent wear resistance to maintain effectiveness even under the harshest grinding conditions. These balls maintain their shape and size over extended periods, minimizing wear and reducing the frequency of replacements. The result is lower maintenance costs and reduced downtime for mining operations.

Contact Now

Introduction of the productThe high hardness of the Forged Grinding Ball with High Hardness (58-63HRC) allows for improved grinding efficiency by facilitating better energy transfer during the milling process. The increased hardness ensures consistent performance, maintaining high grinding capacity and throughput over extended periods. This optimized grinding performance leads to a more efficient particle size reduction, ultimately improving product quality and reducing energy consumption.

Contact Now