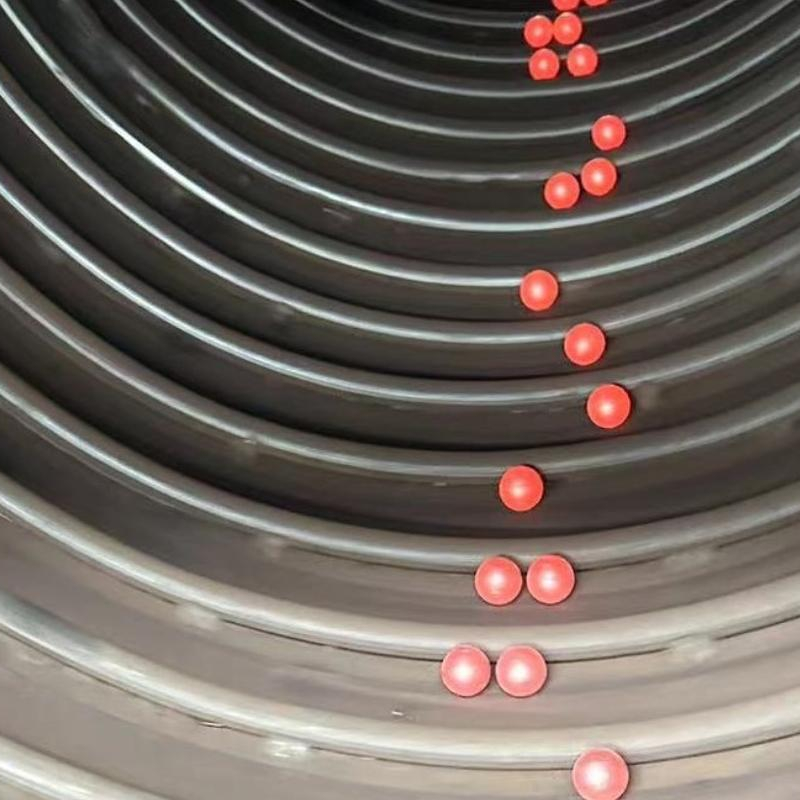

Introduction of the productThe Wet and Dry Grinding Ball Cr(1-32%) offers exceptional wear resistance, ensuring longer life and reduced downtime. The higher chromium balls (32%) are specifically engineered to withstand abrasive conditions, delivering superior hardness and corrosion resistance. This results in less frequent replacements and improved grinding efficiency.

Contact Now

Introduction of the productWith its chromium content, the 1-32% Cr Casting Grinding Ball delivers exceptional durability and wear resistance. The higher chromium balls exhibit excellent hardness and corrosion resistance, significantly reducing the wear rate during grinding operations. Even in harsh conditions, these grinding balls maintain their shape and integrity for longer periods, contributing to reduced replacement costs and improved productivity.

Contact Now

Introduction of the productThanks to its precise manufacturing process, the 10-32% Cr Cast Grinding Ball ensures efficient grinding performance. The uniform hardness and optimal surface finish of these balls allow for consistent grinding, improving productivity while reducing energy consumption. Their ability to deliver fine, uniform results makes them a valuable asset in both coarse and fine grinding applications.

Contact Now

Introduction of the productThe Cast Grinding Ball For Wet and Dry Grinding excels in both wet and dry grinding processes, offering versatile performance across various industrial applications. Whether grinding soft materials or more abrasive substances, these balls provide efficient energy transfer and consistent grinding results. The optimized design ensures smooth particle breakdown and enhances throughput in mills, making them suitable for industries such as mining, cement, and metallurgy.

Contact Now

Introduction of the productThe Grinding Steel Ball For Wet and Dry Grinding (20-160mm) is engineered to deliver optimal grinding efficiency in a variety of milling operations. With sizes ranging from 20mm to 160mm, these grinding balls offer superior performance in breaking down materials, improving particle size distribution, and enhancing throughput. The uniform size and hardness of the balls allow for smooth and consistent grinding, whether the operation is dry or wet.

Contact Now

Introduction of the productThe Hot Rolled/Forged Steel Ball for Dry and Wet Grinding is engineered to maximize grinding efficiency. Its consistent hardness and smooth surface provide optimal energy transfer during the milling process, ensuring efficient breakdown of materials in both dry and wet grinding applications. The uniform shape and size of these balls reduce friction, allowing for smoother operation and improved throughput.

Contact Now

Introduction of the productThe Forged Mill Ball (Wet and Dry Grinding) excels in both wet and dry grinding applications, offering versatility across a wide range of industries. The uniform hardness and smooth surface finish enhance the efficiency of material breakdown and energy transfer, making it suitable for grinding soft ores as well as more abrasive materials.

Contact Now

Introduction of the productThese 1/2.5/3/3.5/4 Inch Grinding Balls are manufactured with high-quality materials to ensure exceptional durability and performance. Their uniform hardness and smooth surface allow for consistent and efficient energy transfer, maximizing grinding performance while minimizing energy consumption. Built to withstand heavy impact and abrasive forces, these grinding balls offer extended service life, reducing the need for frequent replacements and minimizing downtime in milling operations.

Contact Now

Introduction of the productThe Hot Rolled Ball with Low Breakage Rate provides optimized grinding performance, offering high efficiency in both wet and dry grinding applications. The ball’s unique manufacturing process ensures a consistent and uniform structure, leading to minimal wear and enhanced grinding efficiency. With a low breakage rate, these balls deliver more effective material reduction, resulting in improved particle size distribution and higher throughput.

Contact Now

Introduction of the productThe Forged/Hot Rolled Grinding Media Grinding Ball is designed to maximize grinding efficiency by providing consistent performance throughout the grinding process. Its uniform hardness and smooth surface allow for better energy transfer during milling, ensuring more efficient breakdown of materials. Whether used in dry or wet grinding, these grinding balls enhance the overall throughput and improve particle size distribution.

Contact Now

Introduction of the productThe Grinding Steel Rods For Sand / Iron / Coal Grinding deliver exceptional grinding efficiency, thanks to their uniform hardness and smooth surface. These rods facilitate more effective material breakdown, leading to improved particle size distribution and better throughput. Whether used in wet or dry grinding, the design of the rods ensures optimal contact with the material, enhancing grinding performance.

Contact Now

Low Breakage Rate for Enhanced Production EfficiencyThe breakage rate is a key indicator of the quality of Grinding Rods For Mining . Utilizing advanced manufacturing techniques and carefully selected materials, our grinding rods achieve an exceptionally low breakage rate, typically maintained at ≤1%. This ensures durability during prolonged grinding operations, minimizing the need for frequent replacements and maintenance.

Contact Now

Introduction of the productThe High and Super High Chromium Cast Grinding Ball is designed to maximize grinding efficiency by offering consistent performance and reliable results. The uniform hardness and smooth surface finish of these balls ensure optimal grinding performance with minimal energy consumption. Their ability to maintain their shape and size throughout the grinding process improves grinding efficiency, resulting in finer material particle size and higher throughput.

Contact Now

Introduction of the productThe Forged Grinding Ball For SAG And Ball Mill is designed to optimize grinding efficiency in both SAG and ball mills. Its uniform hardness and smooth surface minimize friction during the grinding process, leading to better energy transfer and more efficient material breakdown. These balls ensure consistent grinding performance, contributing to improved throughput, reduced energy consumption, and better particle size reduction.

Contact Now

Introduction of the productThe Grinding Ball For Fine Grinding is specifically engineered to optimize grinding performance. Their uniform hardness and smooth surface help in achieving consistent, fine particle sizes while minimizing energy consumption. These balls are designed to efficiently break down materials into finer particles, providing enhanced throughput and improved product quality.

Contact Now

Introduction of the productThe Grinding Ball For Cement Power Station is designed to enhance grinding efficiency, ensuring superior performance during the grinding of raw materials and clinker. Their uniform hardness and smooth surface enable better energy transfer, improving particle breakdown and material throughput. This results in consistent and high-quality cement production with reduced energy consumption.

Contact Now

Introduction of the productThe B2 B3 B6 BU BG Hot Rolled Grinding Ball is designed to offer exceptional grinding efficiency. Its uniform hardness and precise dimensions ensure consistent performance, allowing for better energy transfer and efficient material breakdown during the milling process. Whether used for coarse grinding or fine grinding, these hot-rolled balls help to improve throughput while reducing energy consumption.

Contact Now

Hot rolled grinding ball Product DetailsAlthough the initial investment in hot rolled steel balls is higher, their longer service life and lower replacement costs can significantly reduce overall operational costs in the long run, enhancing the economic efficiency of the business.Application in grinding machines and areasMachinesIndustries·Ball mills·Mining industry·SAG mills·Power stations·Tower mills·Cement industry·Coal grinding machine·Steel Industry·Bearing·Chemical Industry·Metallurgical industryTechnical dataChemical Composition (%)Steel SpecificationCMnSiCrSP40Cr0.37-0.440.50-0.800.17-

Contact Now

Introduction of the productThe 20-160mm Forged Grinding Ball delivers optimized grinding performance through its uniform hardness and smooth surface. Its size and composition are ideal for efficient energy transfer, enabling better material breakdown and consistent particle size reduction. This efficient energy transfer improves throughput while reducing energy consumption, helping to lower operational costs.

Contact Now

Introduction of the productThanks to its consistent hardness and smooth surface finish, the Hot Rolled Steel Grinding Ball enhances the efficiency of the grinding process. The ball's high structural integrity allows for more effective energy transfer, ensuring better material reduction and improved throughput. This leads to a more efficient grinding process, requiring less energy to achieve the same or better results.

Contact Now

Introduction of the productThis Casting Chrome Grinding Ball is a high-quality grinding ball designed to provide superior performance and long-lasting durability. Manufactured using a high chromium alloy and heat-treated to ensure optimum hardness and strength, these balls are designed to provide superior resistance to wear and corrosion.

Contact Now

Introduction of the productThe high hardness of the Forged Grinding Ball with High Hardness (58-63HRC) allows for improved grinding efficiency by facilitating better energy transfer during the milling process. The increased hardness ensures consistent performance, maintaining high grinding capacity and throughput over extended periods. This optimized grinding performance leads to a more efficient particle size reduction, ultimately improving product quality and reducing energy consumption.

Contact Now

Introduction of the productThe Grinding Cast Ball for Copper, Gold, Iron, Lithium is engineered for durability, featuring excellent wear resistance to maintain effectiveness even under the harshest grinding conditions. These balls maintain their shape and size over extended periods, minimizing wear and reducing the frequency of replacements. The result is lower maintenance costs and reduced downtime for mining operations.

Contact Now

Introduction of the productThe Hot Rolled/Forged Grinding Ball for Copper, Gold, Iron, Silver is specifically designed to enhance grinding efficiency and optimize metal recovery in milling operations. These balls provide excellent energy transfer during the grinding process, improving material breakdown and ensuring better throughput. The uniformity of the ball size and hardness helps to minimize friction and reduce energy consumption, contributing to smoother operations.

Contact Now