Ball Mill Wear Liner Plate

Ball Mill Wear Liner Plate is a crucial component in ball mills used for grinding materials in various industries, including mining, cement, and metallurgy. These liner plates are designed to protect the mill shell from wear and damage during the grinding process. Made from high-quality materials such as high chromium alloys and steel, Ball Mill Wear Liner Plates provide excellent resistance to abrasion and impact, ensuring that the mill operates at peak efficiency. By reducing wear, these plates extend the lifespan of the mill, minimizing maintenance and downtime.

Introduction of the product

The main advantage of Ball Mill Wear Liner Plates is their high abrasion resistance and impact strength. These plates are engineered to withstand the harsh conditions of grinding, where constant impact and friction can cause significant wear. By using advanced alloy materials, the liner plates offer superior hardness and toughness, making them ideal for industries where heavy-duty grinding is required. The durability of these plates reduces the frequency of replacements and ensures that grinding operations remain efficient for longer periods.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Technical Parameters | ||||

Item | Application Range | Working Life (Years) | Rockwell Hardness (HRC) | Impact Value (J/m²) |

High Toughness High Chromium Cast Iron | ≤Φ5M Ball Mill Liner, Aside Liners, etc. | ≥7 Years | HRC≥60 | 8-10 |

High Chromium Cast Iron I | ≤Φ5M Ball Mill Liner, Vertical Mill Liners, etc. | ≥6 Years | HRC≥60 | 7-9 |

High Chromium Cast Iron II | ≤Φ4.2M Ball Mill Liner, Separater Liners, etc. | ≥5 Years | HRC≥58 | 6-8 |

High Chromium Cast Iron III | ≤Φ4.2M Ball Mill Liner, Aside Liners, Partition Plates, etc. | ≥4 Years | HRC≥55 | 6-9 |

Chromium Platinum Nickel Alloy Steel | ≤Φ5M Ball Mill Liner, Aside Liners, Partition Plates, Impact Plates, etc. | ≥4 Years | HRC≥52 | ≥40 |

Middle Carbon Alloy Steel | ≥3 Years | HRC≥50 | ≥30 | |

Middle Chromium Alloy Steel | ≥2 Years | HRC≥48 | ≥20 | |

Low Chromium Alloy Steel | ≥1.5 Years | HRC≥45 | ≥40 | |

Low Carbon High Chromium Alloy Steel | Mining Wet Grinding Liners Plate, Aside Liners, Grid Place Etc Big Raw Material Mill,Etc | ≥1 Years | HRC≥46 | ≥50 |

≥3 Years | ||||

High Manganese Steel (Mn13) | Mining Wet Grinding Liners Plate, Aside Liners, Grid Place Etc | ≥8 Months | HB≥200 | ≥147 |

High Manganese Alloy Steel (Mn13Cr2) | Crusher Impact Plate, Jaw Crusher Plates | ≥1 Years | HB≥220 | ≥120 |

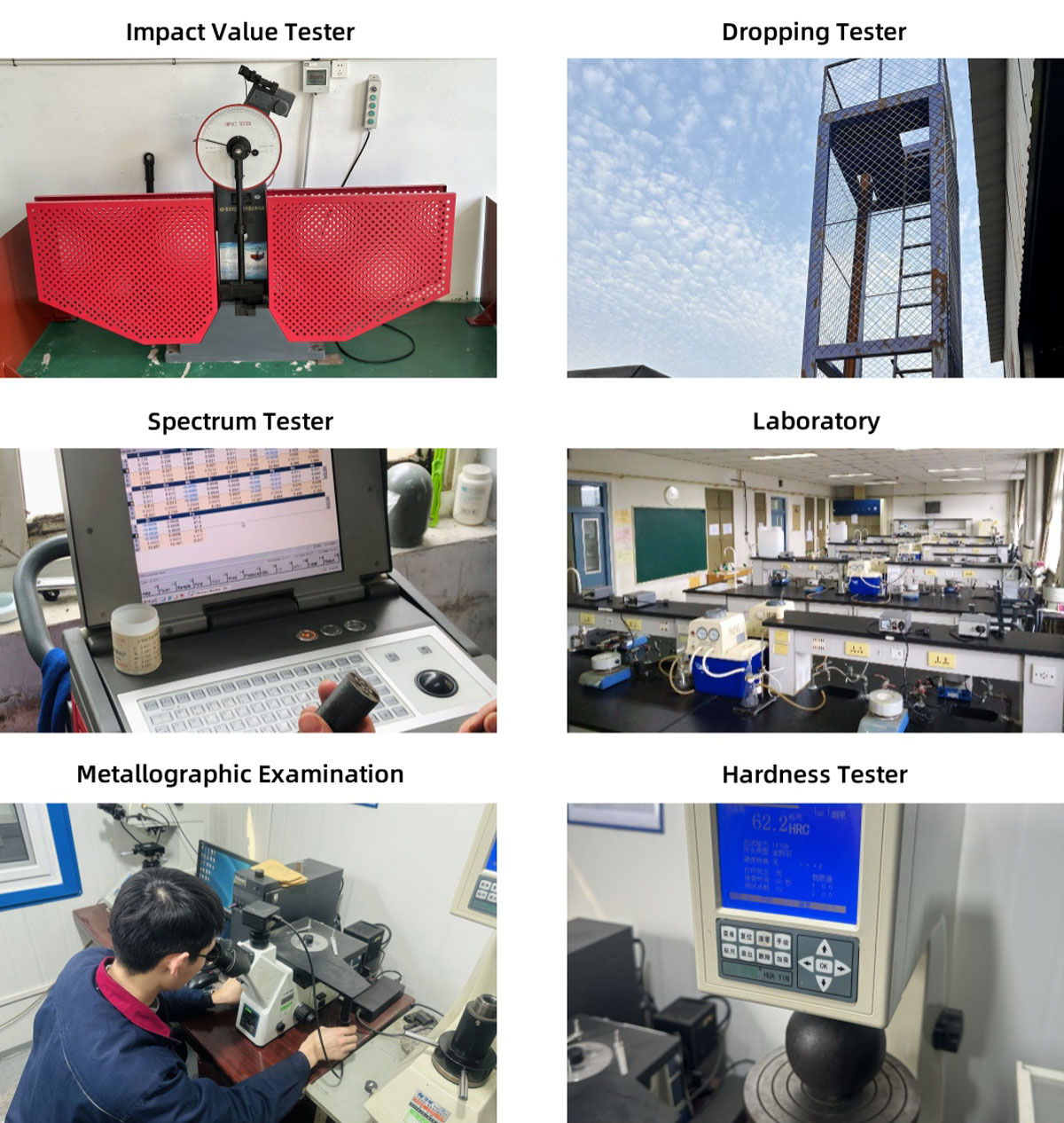

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

We offer Ball Mill Wear Liner Plates in a variety of designs, tailored to meet the specific needs of different types of mills. Whether you require liner plates with specific hardness, thickness, or shape, we can customize the design to optimize the performance of your grinding mill. By ensuring a perfect fit, our custom-made liner plates contribute to better grinding efficiency and less wear on both the liners and the mill itself. This customization option helps enhance the overall productivity of your milling operations.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible