Grinding Cast Ball For Copper Gold Iron Lithium

The Grinding Cast Ball for Copper, Gold, Iron, Lithium is designed to deliver exceptional performance across a range of mineral processing applications. Whether you're working with copper, gold, iron, or lithium ores, these grinding balls provide optimized efficiency for each specific material. Their unique formulation ensures they can handle the distinct characteristics of different minerals, enabling high-quality grinding and improved recovery rates. This versatility makes them an essential tool in the mining industry, where precision and performance are critical.

Introduction of the product

The Grinding Cast Ball for Copper, Gold, Iron, Lithium is engineered for durability, featuring excellent wear resistance to maintain effectiveness even under the harshest grinding conditions. These balls maintain their shape and size over extended periods, minimizing wear and reducing the frequency of replacements. The result is lower maintenance costs and reduced downtime for mining operations. Whether used for coarse or fine grinding, these cast balls deliver consistent performance, maximizing operational efficiency while extending their service life.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||||||

Name | C | Si | Mn | Cr | Mo | S | P | Cu | Ni | |

ZQCr26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.0-30.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.0-23.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.0-18.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.0-14.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

Middle Chromium Alloy Cast Balls | ZQCr8 | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | 0-1.0 | ≤0.06 | ≤0.10 | 0-0.8 | - |

ZQCr5 | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - | |

Low Chromium Alloy Cast Balls | ZQCr2 | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - |

Bainite Alloy Cast Balls | ZQQTB | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | ≤0.03 | ≤0.10 | - | - |

ZQQTM | 3.2-3.8 | 2.0-3.5 | 0.5-1.5 | - | - | ≤0.03 | ≤0.10 | - | - | |

| Physical Features | |||||||

| Name | Surface Hardness (HRC) | Impact Value (J/cm²) | Breakage Rate (%) | Diameter Tolerance (mm) | Diameter (mm) | Drop Test (Times) | |

| High Chromium Alloy Cast Balls | ZQCr26 | ≥58 | ≥4J | ≤1.0 | Φ≤30 +1.0 -1.0 30<Φ≤60 +1.5 -1.0 60<Φ≤80 +2.0 -1.0 80<Φ≤100 +2.5 -1.0 Φ>100 +3.0 -1.0 | 10-160 | >15000 |

| ZQCr20 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr15 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr12 | ≥58 | ≥4J | ≤1.0 | ||||

| Middle Chromium Alloy Cast Balls | ZQCr8 | ≥48 | ≥4J | ≤1.0 | |||

| ZQCr5 | ≥47 | ≥4J | ≤1.0 | ||||

| Low Chromium Alloy Cast Balls | ZQCr2 | ≥45 | ≥4J | ≤1.0 | |||

| Bainite Alloy Cast Balls | ZQQTB | ≥50 | ≥4J | ≤1.0 | |||

| ZQQTM | ≥52 | ≥4J | ≤1.0 | ||||

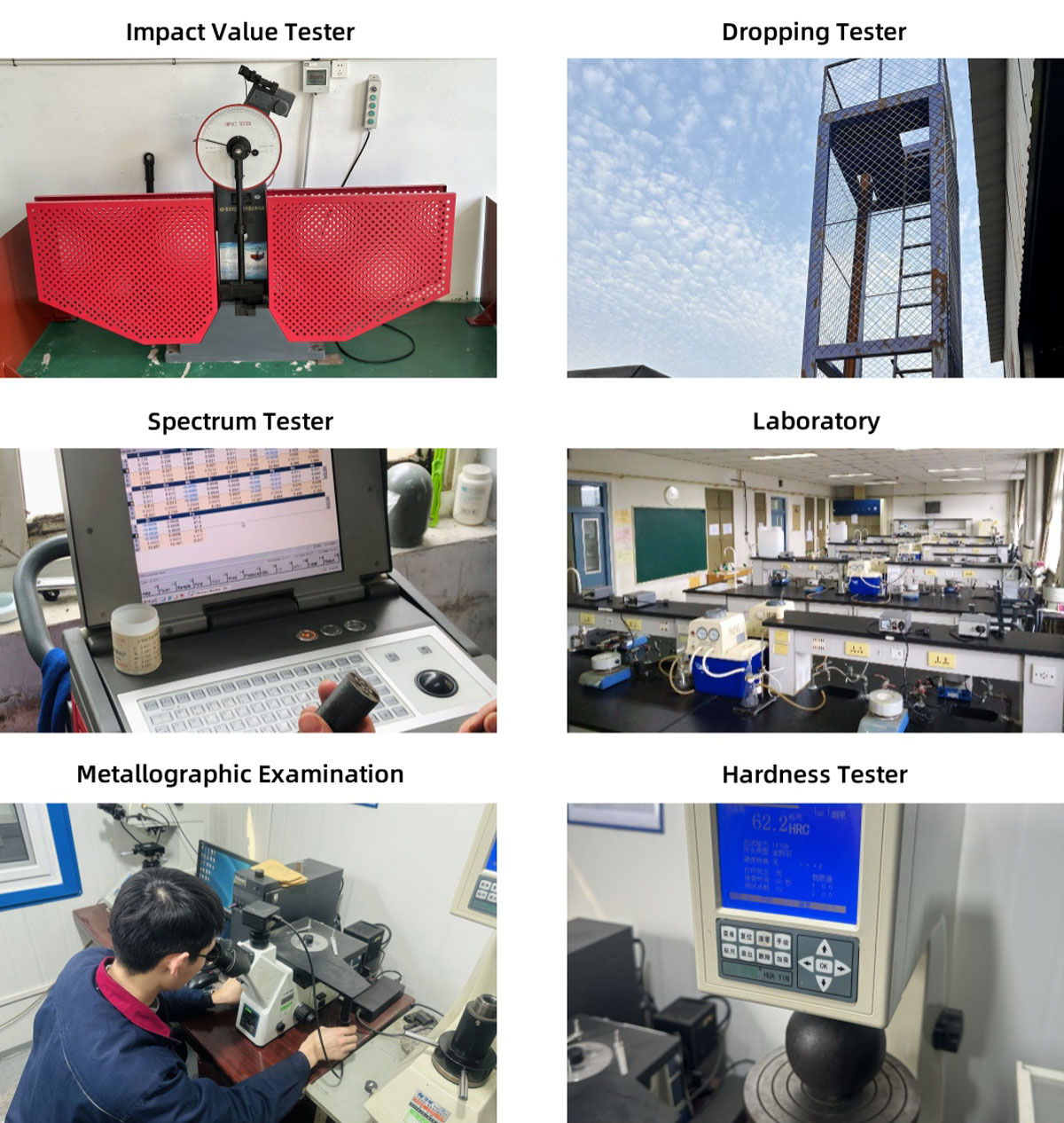

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

The Grinding Cast Ball for Copper, Gold, Iron, Lithium can be customized to meet the precise needs of various grinding processes. With options for different sizes, hardness, and alloy compositions, these grinding balls can be tailored for each type of mineral being processed. Customization ensures that the balls are perfectly suited to the demands of your operation, resulting in more efficient grinding, improved throughput, and reduced energy consumption. This flexibility makes them an invaluable asset for mineral processing across a variety of mining sectors.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible