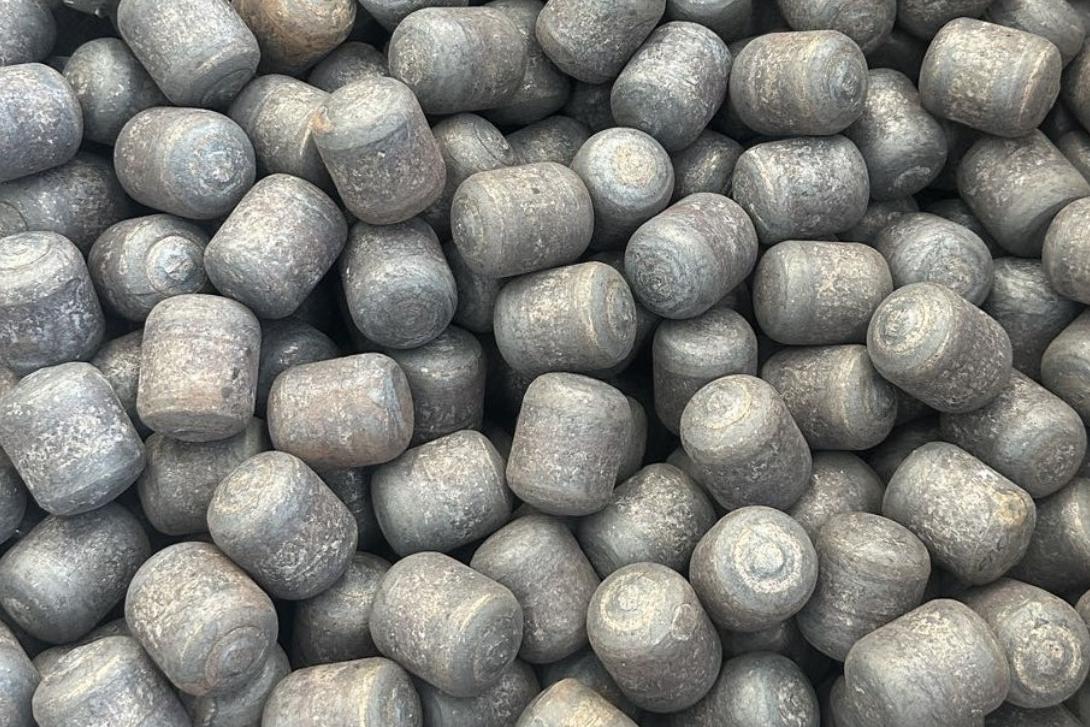

Forged Steel Cylinders

Forged Steel Cylinders are manufactured using high-quality steel and advanced forging processes to ensure exceptional strength, durability, and performance. These cylinders are designed to withstand high pressure, heavy loads, and harsh environments, making them ideal for heavy-duty applications such as mining, oil and gas, and construction. Their superior resistance to wear and impact ensures a long service life, making them a reliable choice for industries that demand high-performance components.

Introduction of the product

Manufactured with strict quality control processes, Forged Steel Cylinders offer precise dimensions and uniform material properties, which enhance performance and reliability. These cylinders can be customized to meet the specific requirements of various applications, including different sizes, tolerances, and mechanical properties. Their precision and flexibility make them highly adaptable to various industries, from construction machinery to energy production, ensuring optimal performance in each unique application.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | ||||||

Diameter × Length (mm) | Surface Hardness(HRC) | Diameter Tolerance (mm) | Length Tolerance (mm) | Impact Value(J/cm²) | Breakage Rate (%) | Drop Test (times) |

Φ20×25 | 60-66 | +1.2 -1.0 | +1.5 -1.5 | ≥12 | ≤1 | >15000 |

Φ25×30 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ30×35 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ30×40 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ35×40 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ35×45 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ40×50 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ45×55 | +2.0 -2.0 | +2.5 -2.5 | ||||

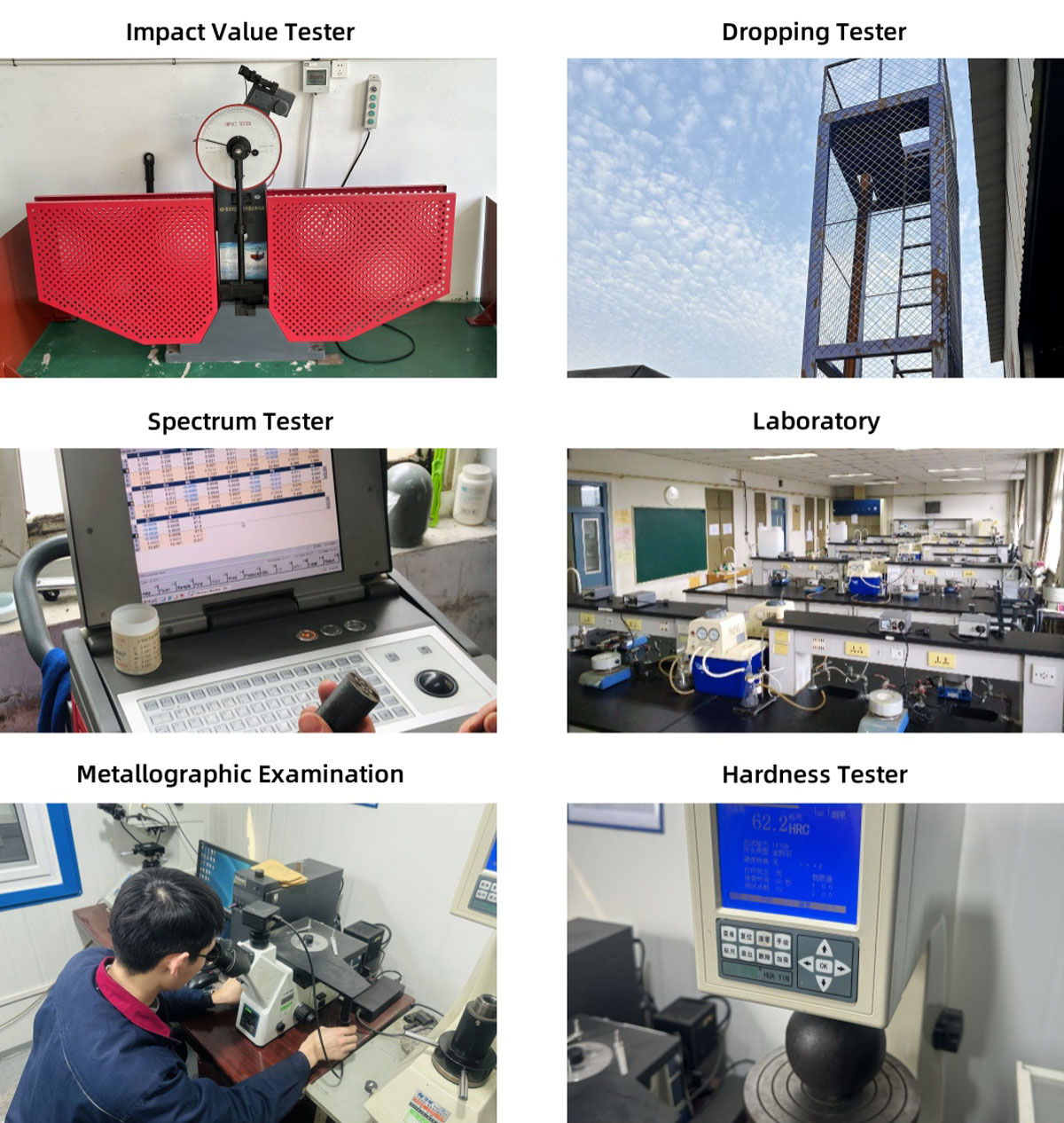

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

Forged Steel Cylinders are known for their high efficiency and cost-effectiveness. Their robust design and long service life reduce the need for frequent replacements and maintenance, making them a cost-efficient solution for demanding applications. Their ability to perform reliably under heavy stress and extreme conditions also results in reduced downtime and enhanced productivity. As industries continue to seek ways to reduce costs while maintaining high performance, Forged Steel Cylinders provide an ideal balance between cost and efficiency.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible