Forged Steel Cylpebs

Forged Steel Cylpebs are high-quality grinding media made from high-carbon steel through a forging process, widely used in mining, chemical, power, and other industries for grinding operations. Compared to traditional cast steel balls, Forged Steel Cylpebs offer superior strength and toughness, providing a longer service life. Their unique cylindrical shape helps improve grinding efficiency during the milling process, reducing material consumption. Additionally, Forged Steel Cylpebs have uniform surface hardness and a dense internal structure, offering better wear resistance and impact resistance, making them particularly suitable for high-load, high-wear environments.

Introduction of the product

Our Forged Steel Cylpebs are manufactured using advanced forging technology, which effectively eliminates internal defects that may arise during the casting process, resulting in a more uniform microstructure. The forging process, through high-temperature heating, hammering, and extrusion, refines the steel's grain, significantly enhancing its mechanical properties. With precise temperature control and processing, the final Forged Steel Cylpebs have a smooth surface and high dimensional accuracy, making them suitable for use with various grinding equipment. Thanks to this process, Forged Steel Cylpebs provide higher processing efficiency, extend equipment lifespan, and reduce maintenance costs in practical applications.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | ||||||

Diameter × Length (mm) | Surface Hardness(HRC) | Diameter Tolerance (mm) | Length Tolerance (mm) | Impact Value(J/cm²) | Breakage Rate (%) | Drop Test (times) |

Φ20×25 | 60-66 | +1.2 -1.0 | +1.5 -1.5 | ≥12 | ≤1 | >15000 |

Φ25×30 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ30×35 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ30×40 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ35×40 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ35×45 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ40×50 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ45×55 | +2.0 -2.0 | +2.5 -2.5 | ||||

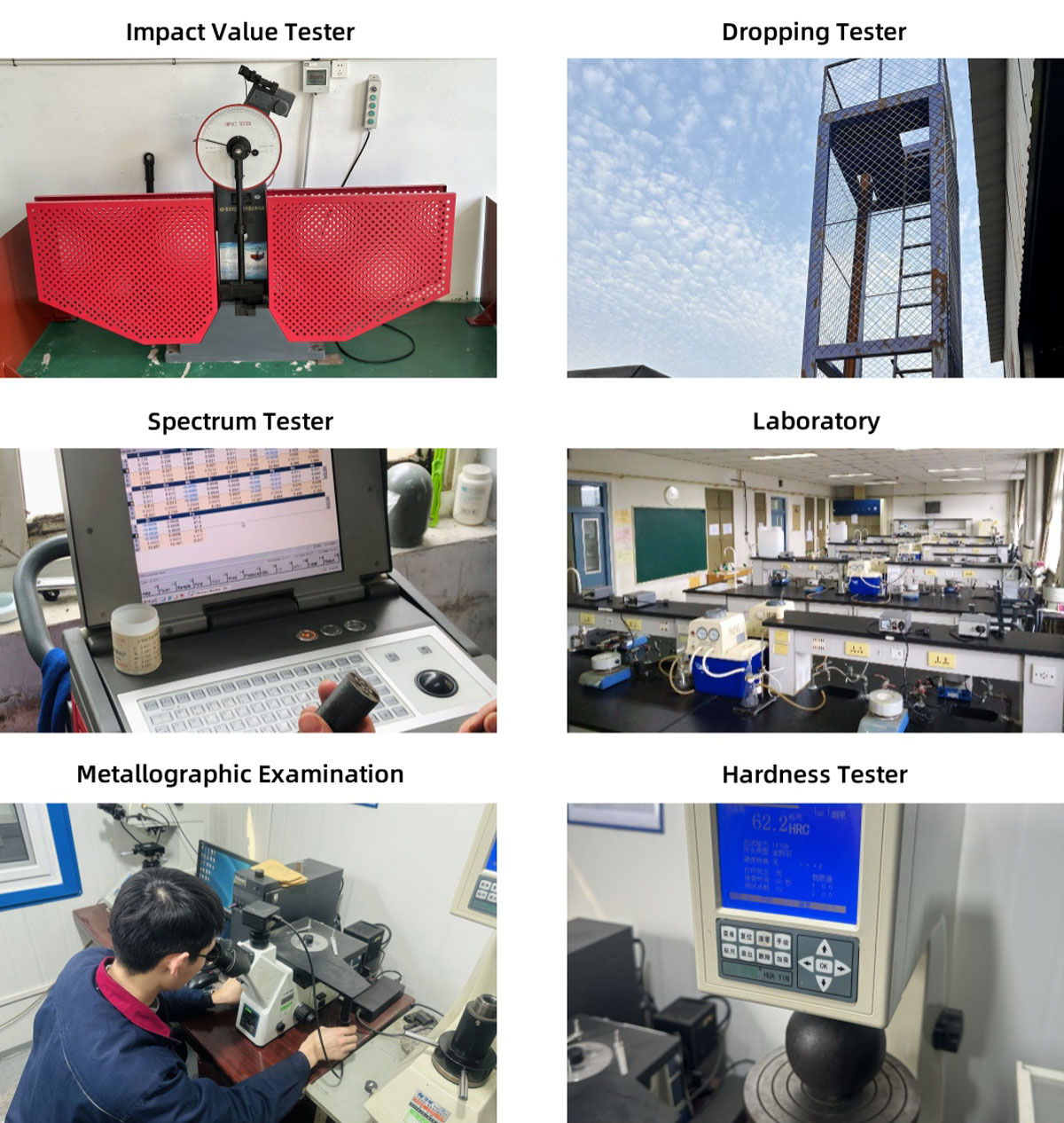

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

Our Forged Steel Cylpebs are suitable for a variety of grinding operations, including but not limited to the grinding of cement, ores, and coal minerals. Unlike standard grinding balls, we also offer customization services, allowing us to adjust the size and hardness of the Forged Steel Cylpebs according to specific customer requirements to suit different working environments. At the same time, our production facilities are equipped with high-precision inspection equipment, ensuring that every batch of Forged Steel Cylpebs meets strict quality standards. Whether in regular production or special customization requests, our Forged Steel Cylpebs provide customers with efficient, economical, and reliable solutions.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible