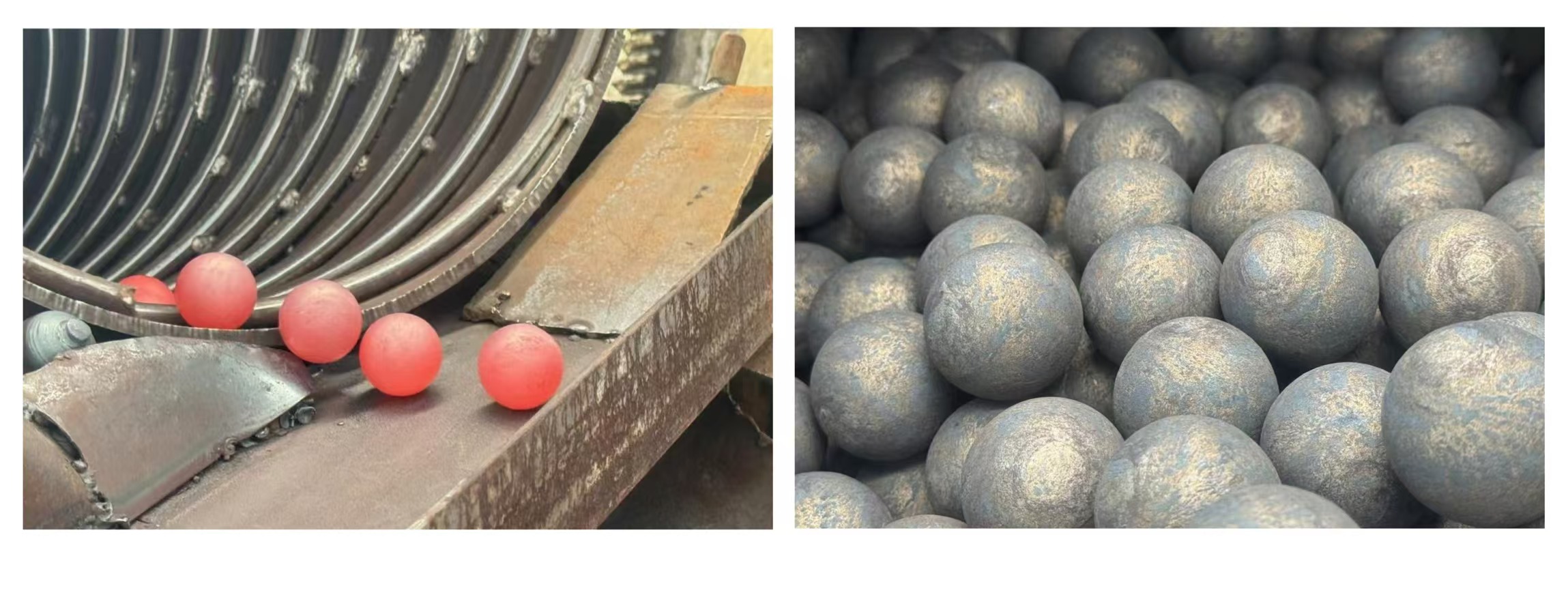

Hot-rolled Grinding Ball

Hot-rolled Grinding Balls are essential for high-performance milling operations across various industries, including mining, cement, and power generation. These grinding balls are produced using advanced hot-rolling technology, which provides superior strength and durability. The process ensures that each ball has consistent hardness and is capable of withstanding the most demanding grinding conditions, delivering superior grinding efficiency and longer service life.

Introduction of the product

The unique hot-rolling process used for Hot-rolled Grinding Balls significantly enhances their durability. The heating and rolling stages provide a uniform microstructure, resulting in a product that exhibits high toughness, reduced wear, and consistent performance. This manufacturing technique ensures that the balls maintain their shape and effectiveness over extended periods, reducing the frequency of replacements and minimizing downtime.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

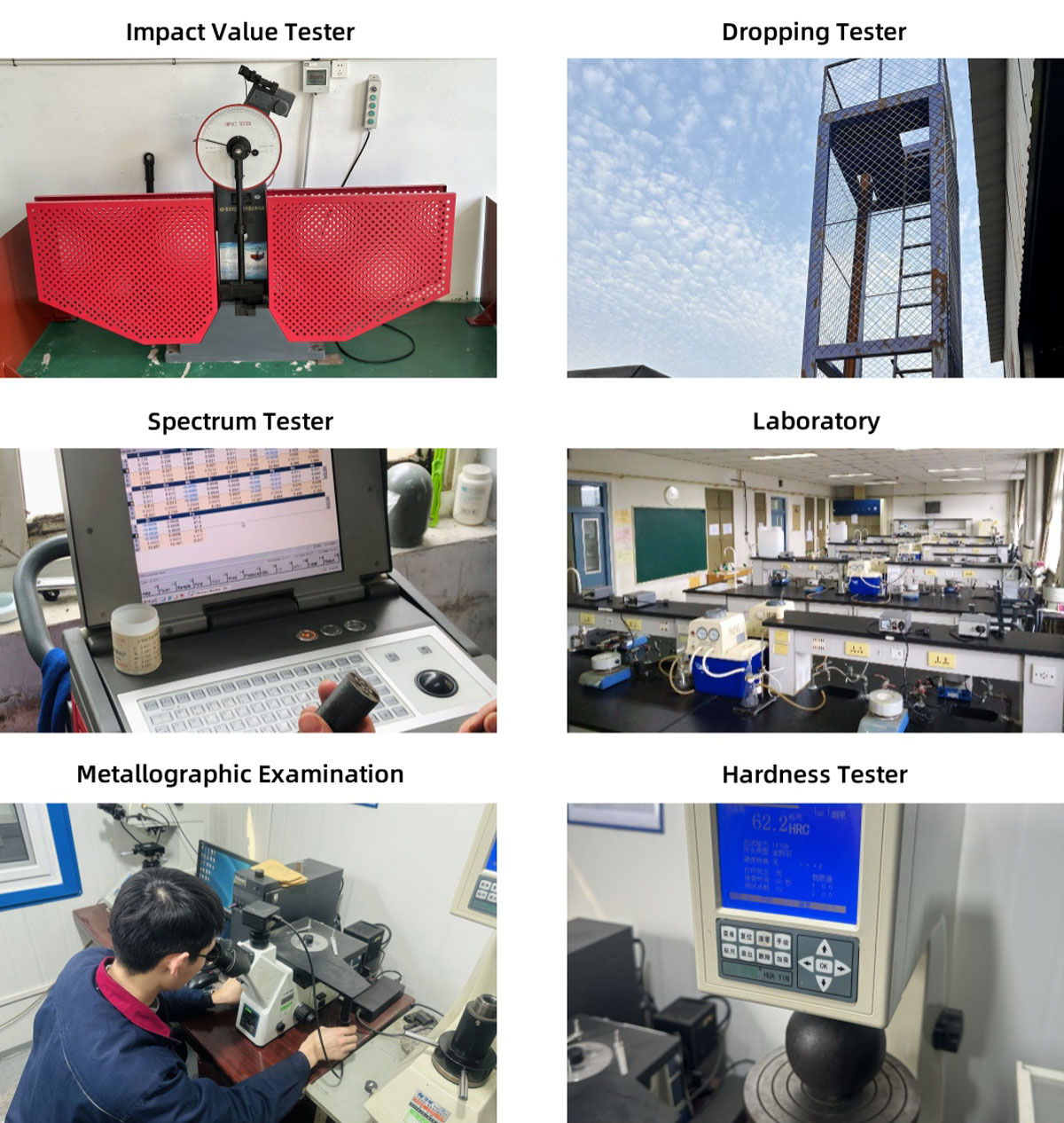

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

We understand that every grinding operation has unique requirements. That’s why our Hot-rolled Grinding Balls can be customized in terms of diameter, hardness, and alloy composition to meet specific needs. Whether you need a certain size for your mill or a particular hardness level, we offer tailored solutions to optimize grinding performance and meet your production goals efficiently.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible