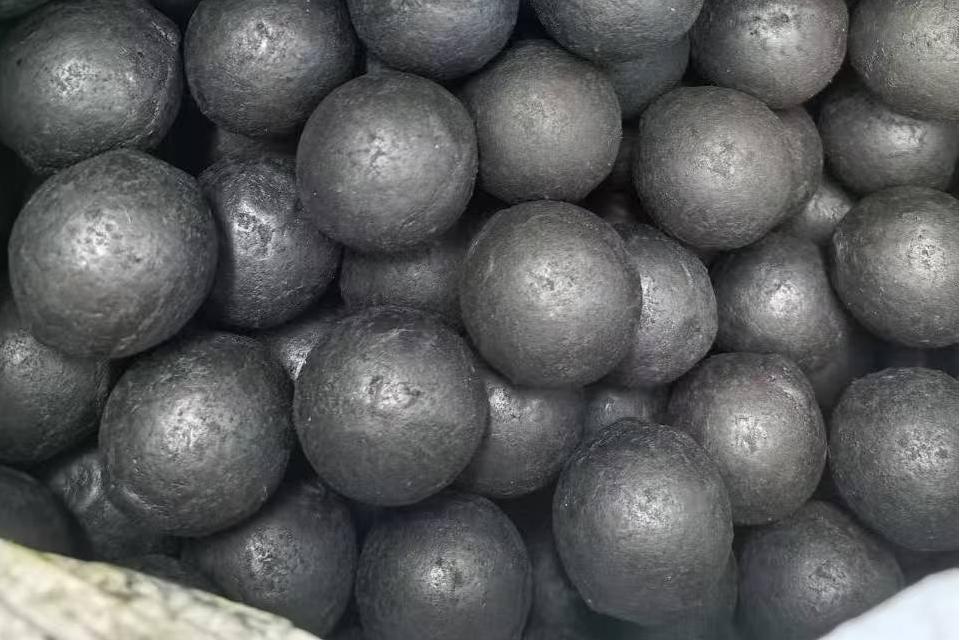

Cast Grinding Ball For Wet And Dry Grinding

The Cast Grinding Ball For Wet and Dry Grinding is designed to provide outstanding durability and wear resistance in both wet and dry grinding environments. Made from high-quality casting materials, these grinding balls are engineered to withstand harsh and abrasive conditions in a wide range of milling operations, from mining to cement production. Their robust structure minimizes wear, ensuring a longer service life, fewer replacements, and reduced operational downtime, all of which contribute to more cost-effective milling processes in both wet and dry grinding scenarios.

Introduction of the product

The Cast Grinding Ball For Wet and Dry Grinding excels in both wet and dry grinding processes, offering versatile performance across various industrial applications. Whether grinding soft materials or more abrasive substances, these balls provide efficient energy transfer and consistent grinding results. The optimized design ensures smooth particle breakdown and enhances throughput in mills, making them suitable for industries such as mining, cement, and metallurgy. Their ability to perform reliably in both wet and dry environments makes them a flexible solution for diverse grinding needs.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||||||

Name | C | Si | Mn | Cr | Mo | S | P | Cu | Ni | |

ZQCr26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.0-30.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.0-23.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.0-18.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.0-14.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

Middle Chromium Alloy Cast Balls | ZQCr8 | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | 0-1.0 | ≤0.06 | ≤0.10 | 0-0.8 | - |

ZQCr5 | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - | |

Low Chromium Alloy Cast Balls | ZQCr2 | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - |

Bainite Alloy Cast Balls | ZQQTB | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | ≤0.03 | ≤0.10 | - | - |

ZQQTM | 3.2-3.8 | 2.0-3.5 | 0.5-1.5 | - | - | ≤0.03 | ≤0.10 | - | - | |

| Physical Features | |||||||

| Name | Surface Hardness (HRC) | Impact Value (J/cm²) | Breakage Rate (%) | Diameter Tolerance (mm) | Diameter (mm) | Drop Test (Times) | |

| High Chromium Alloy Cast Balls | ZQCr26 | ≥58 | ≥4J | ≤1.0 | Φ≤30 +1.0 -1.0 30<Φ≤60 +1.5 -1.0 60<Φ≤80 +2.0 -1.0 80<Φ≤100 +2.5 -1.0 Φ>100 +3.0 -1.0 | 10-160 | >15000 |

| ZQCr20 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr15 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr12 | ≥58 | ≥4J | ≤1.0 | ||||

| Middle Chromium Alloy Cast Balls | ZQCr8 | ≥48 | ≥4J | ≤1.0 | |||

| ZQCr5 | ≥47 | ≥4J | ≤1.0 | ||||

| Low Chromium Alloy Cast Balls | ZQCr2 | ≥45 | ≥4J | ≤1.0 | |||

| Bainite Alloy Cast Balls | ZQQTB | ≥50 | ≥4J | ≤1.0 | |||

| ZQQTM | ≥52 | ≥4J | ≤1.0 | ||||

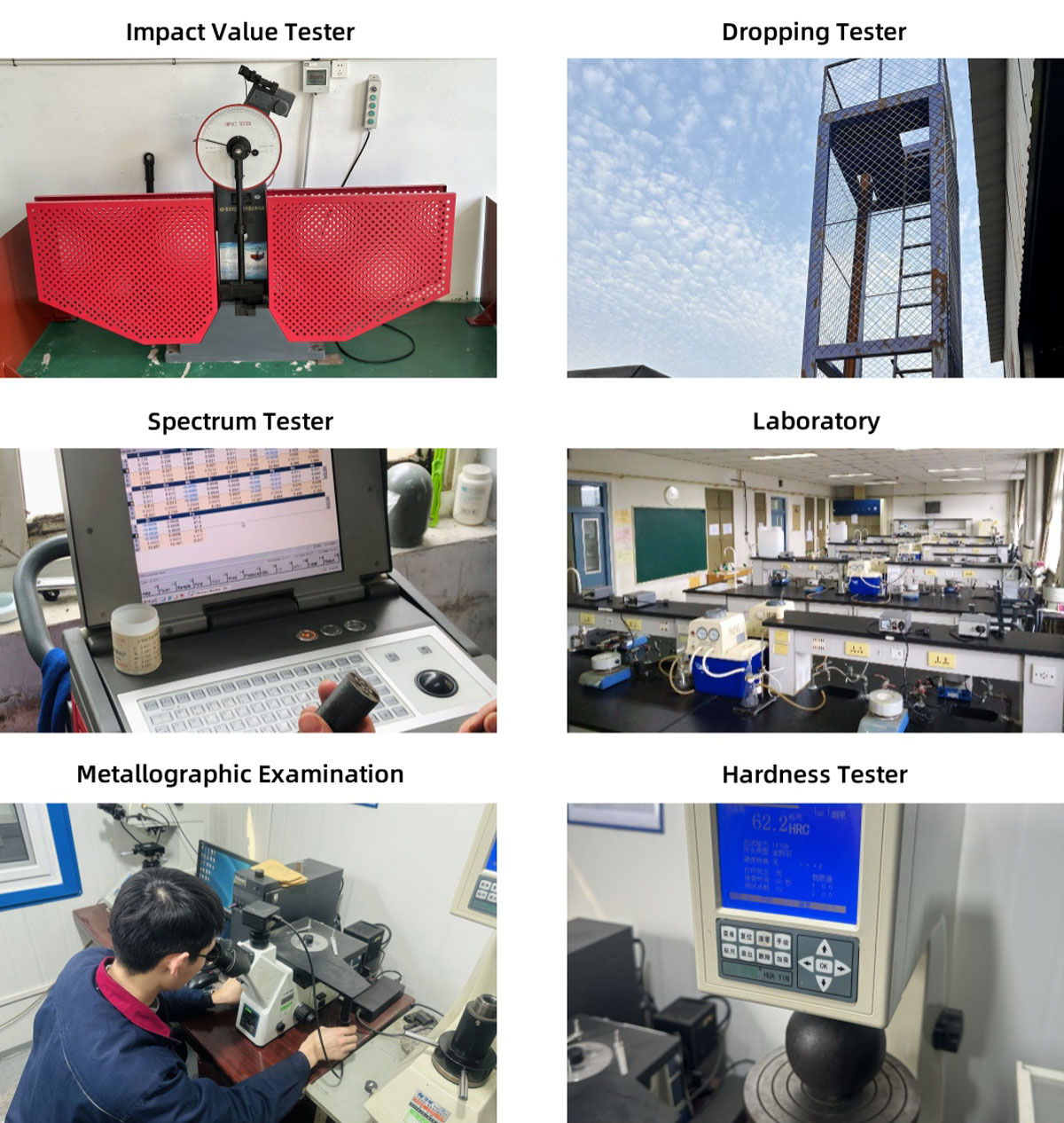

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

To meet the unique requirements of different milling operations, the Cast Grinding Ball For Wet and Dry Grinding can be customized in terms of size, hardness, and material composition. Whether you need smaller balls for fine grinding or larger ones for coarse material reduction, these grinding balls can be tailored to suit your specific needs. This customization ensures that the balls deliver the best balance of wear resistance, grinding efficiency, and cost-effectiveness for your particular application, making them a highly adaptable solution for various industries.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible