Liners Of Mills

The Liners of Mills are designed to offer exceptional durability and resilience, providing reliable protection for mill shells in challenging environments. Crafted from high-quality materials, these liners are engineered to withstand abrasive materials, extreme impacts, and wear over prolonged periods. Their robust construction ensures that they maintain structural integrity, reducing the need for frequent replacements and minimizing downtime in industries such as mining, cement, and steel production.

Introduction of the product

The Liners of Mills are strategically designed to enhance the efficiency of the milling process. Their shape and configuration promote better material flow and improve the grinding action within the mill. By optimizing the energy transfer between the liners and the grinding media, these liners help maximize throughput, reduce energy consumption, and ensure more consistent particle sizes. This leads to higher operational productivity and greater overall cost-effectiveness for milling operations.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Technical Parameters | ||||

Item | Application Range | Working Life (Years) | Rockwell Hardness (HRC) | Impact Value (J/m²) |

High Toughness High Chromium Cast Iron | ≤Φ5M Ball Mill Liner, Aside Liners, etc. | ≥7 Years | HRC≥60 | 8-10 |

High Chromium Cast Iron I | ≤Φ5M Ball Mill Liner, Vertical Mill Liners, etc. | ≥6 Years | HRC≥60 | 7-9 |

High Chromium Cast Iron II | ≤Φ4.2M Ball Mill Liner, Separater Liners, etc. | ≥5 Years | HRC≥58 | 6-8 |

High Chromium Cast Iron III | ≤Φ4.2M Ball Mill Liner, Aside Liners, Partition Plates, etc. | ≥4 Years | HRC≥55 | 6-9 |

Chromium Platinum Nickel Alloy Steel | ≤Φ5M Ball Mill Liner, Aside Liners, Partition Plates, Impact Plates, etc. | ≥4 Years | HRC≥52 | ≥40 |

Middle Carbon Alloy Steel | ≥3 Years | HRC≥50 | ≥30 | |

Middle Chromium Alloy Steel | ≥2 Years | HRC≥48 | ≥20 | |

Low Chromium Alloy Steel | ≥1.5 Years | HRC≥45 | ≥40 | |

Low Carbon High Chromium Alloy Steel | Mining Wet Grinding Liners Plate, Aside Liners, Grid Place Etc Big Raw Material Mill,Etc | ≥1 Years | HRC≥46 | ≥50 |

≥3 Years | ||||

High Manganese Steel (Mn13) | Mining Wet Grinding Liners Plate, Aside Liners, Grid Place Etc | ≥8 Months | HB≥200 | ≥147 |

High Manganese Alloy Steel (Mn13Cr2) | Crusher Impact Plate, Jaw Crusher Plates | ≥1 Years | HB≥220 | ≥120 |

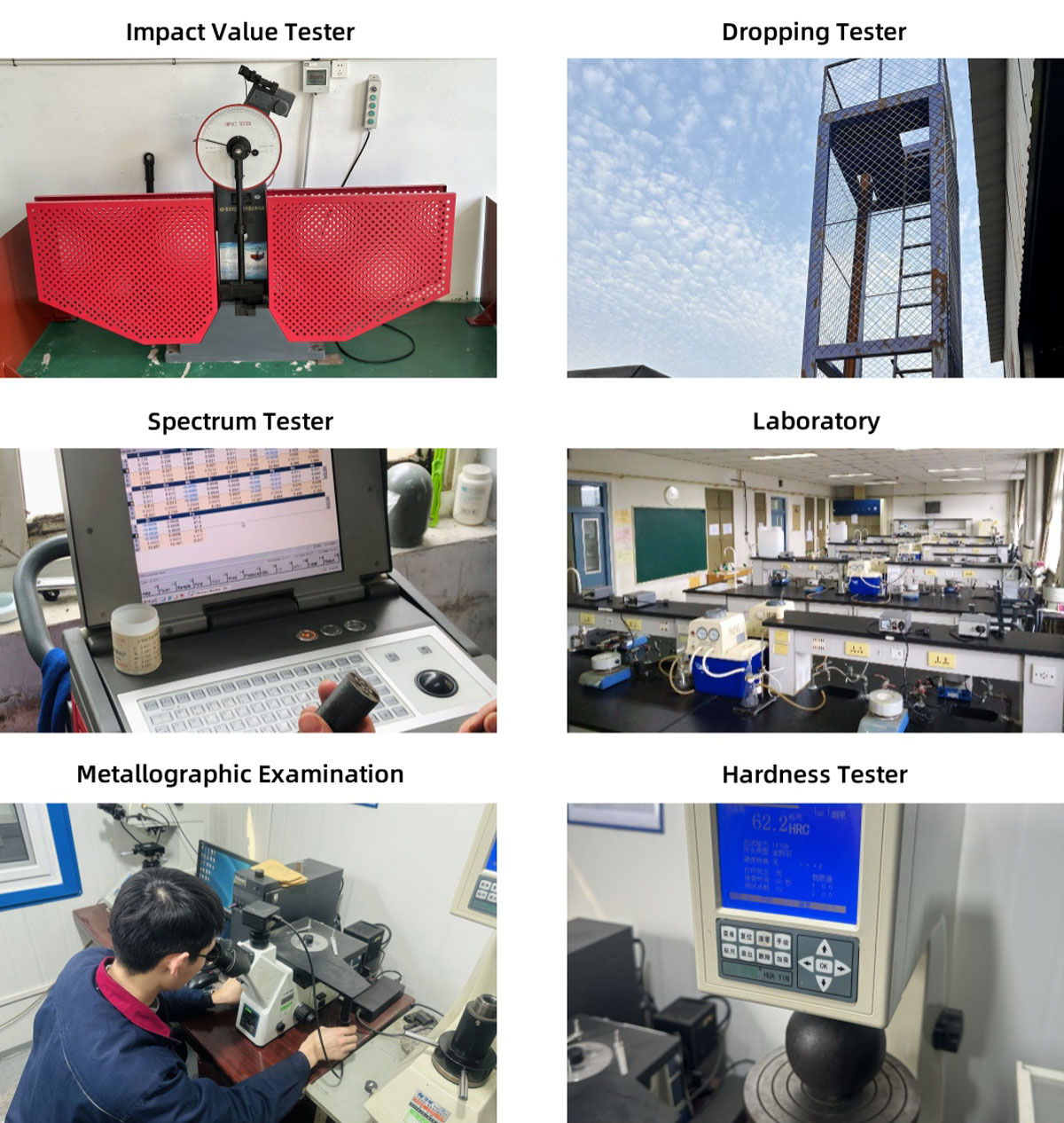

Quality Control Technology and Equipment

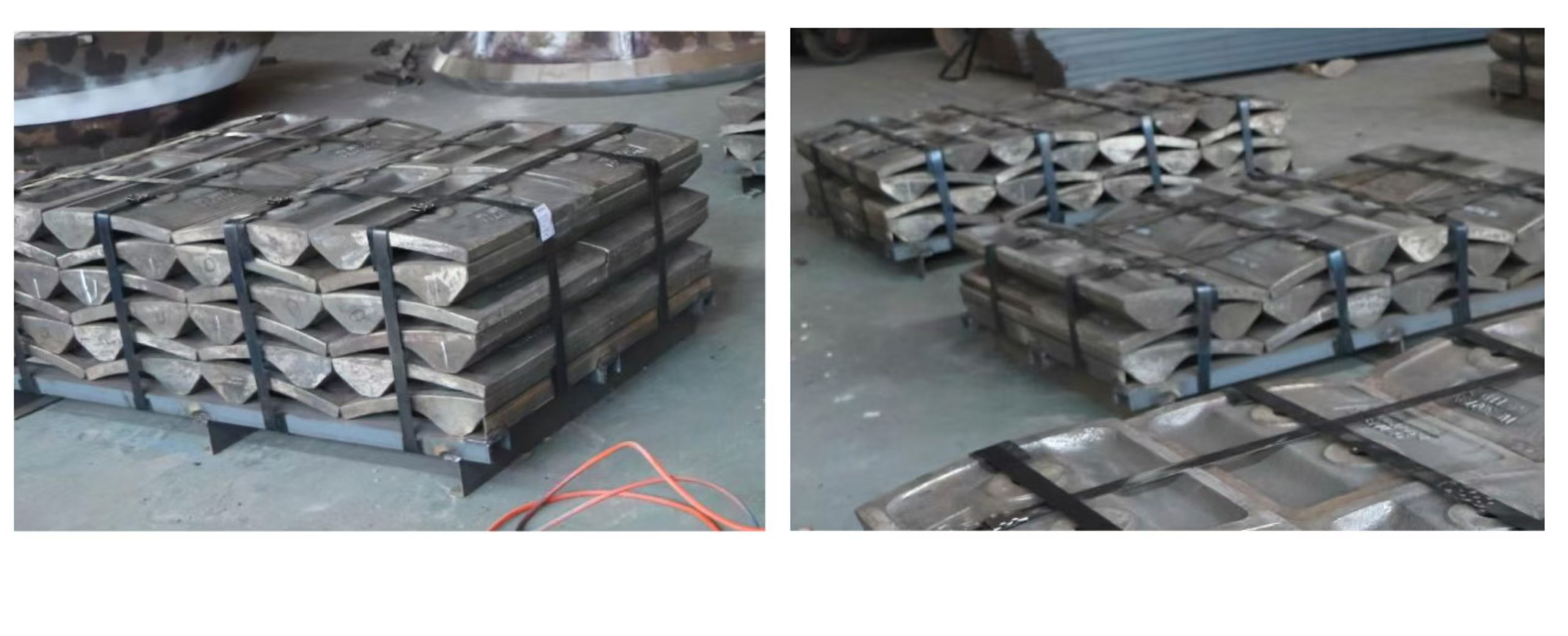

Plants and Production Equipment

Exhibitions

Why choose us

The Liners of Mills can be tailored to meet the unique requirements of different milling processes. Whether it's customizing the material composition, profile, or thickness of the liners, these solutions are adaptable to various mill sizes and operational conditions. This flexibility ensures that mills can perform optimally, regardless of the specific application or material being processed, providing a reliable and cost-effective solution for industries seeking to optimize their milling operations.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible