Grinding Rods

Grinding Rods play a vital role in the mining and milling industries, especially as grinding media in rod mills. The production of our Grinding Rods focuses heavily on precise control of length and diameter, ensuring each rod meets strict dimensional specifications. Through advanced manufacturing processes and precise inspection techniques, we guarantee that the length and diameter of each grinding rod are tightly controlled, ensuring uniform and efficient grinding performance throughout the milling process.

Introduction of the product

The accuracy of the length and diameter of Grinding Rods directly impacts their performance in grinding operations. By rigorously controlling each step of the production process, we ensure that every rod meets the required dimensional standards. This ensures that the grinding media in rod mills are evenly distributed, reducing wear and improving operational efficiency. Furthermore, precise dimensions help minimize equipment wear and maintenance costs, providing customers with enhanced production benefits.

Application in grinding machines and areas

Machines | Industries |

·Rod mills | ·Mining industry |

·Bar mills | ·Power stations |

·Cement industry | |

·Quartz/Silica sand factory | |

·Coal Chemical Industry | |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||||

Steel Specification | Impact Value (J/cm²) | Surface Hardness (HRC) | Diameter (mm) | Length (mm) | Broken Rod Rate (%) | Diameter Tolerance (mm) | Length Tolerance (mm) |

40Cr | ≥12 | 45-60 | 25-140 | 1500-6000 | ≤1 | ±1.5 | ±20 |

42CrMo | |||||||

#45/C45 | |||||||

60Mn | |||||||

65Mn | |||||||

B2 | |||||||

B3 | |||||||

BU | |||||||

BL | |||||||

BG | |||||||

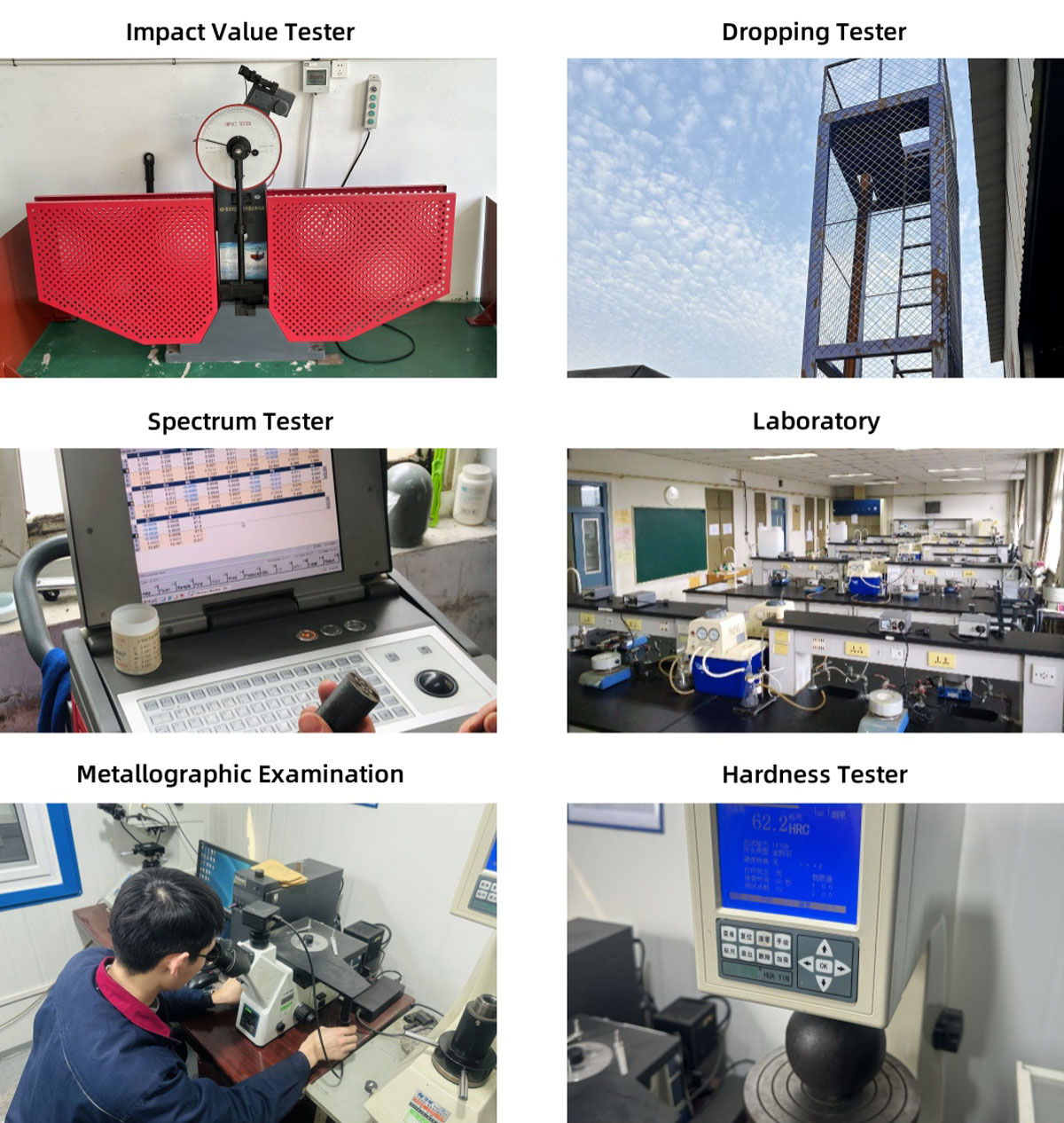

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

To meet the specific needs of our customers, we offer highly customizable Grinding Rods. Whether it's length, diameter, or material composition, we can adjust the specifications according to customer requirements to ensure that each grinding rod is tailored to specific operational conditions. This flexible customization service allows clients to choose the most suitable product for their needs, enhancing grinding efficiency and reducing production costs.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible