SAG Mill Liners

The SAG Mill Liners are crafted to deliver exceptional durability and wear resistance, ensuring the protection of mill shells from severe impacts and abrasion. Designed to withstand the rigorous conditions of semi-autogenous grinding (SAG) mills, these liners reduce the frequency of replacements and extend operational uptime. Their robust construction contributes to maintaining consistent grinding efficiency, making them an indispensable component for heavy-duty milling operations.

Introduction of the product

The SAG Mill Liners are engineered with a focus on improving grinding performance. Their precision design ensures optimal lifting action and material trajectory, enhancing the efficiency of the grinding process. By facilitating effective energy transfer and minimizing slippage, these liners improve throughput and reduce energy consumption. This high level of performance makes them an excellent choice for industries aiming to maximize productivity and operational cost savings.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Technical Parameters | ||||

Item | Application Range | Working Life (Years) | Rockwell Hardness (HRC) | Impact Value (J/m²) |

High Toughness High Chromium Cast Iron | ≤Φ5M Ball Mill Liner, Aside Liners, etc. | ≥7 Years | HRC≥60 | 8-10 |

High Chromium Cast Iron I | ≤Φ5M Ball Mill Liner, Vertical Mill Liners, etc. | ≥6 Years | HRC≥60 | 7-9 |

High Chromium Cast Iron II | ≤Φ4.2M Ball Mill Liner, Separater Liners, etc. | ≥5 Years | HRC≥58 | 6-8 |

High Chromium Cast Iron III | ≤Φ4.2M Ball Mill Liner, Aside Liners, Partition Plates, etc. | ≥4 Years | HRC≥55 | 6-9 |

Chromium Platinum Nickel Alloy Steel | ≤Φ5M Ball Mill Liner, Aside Liners, Partition Plates, Impact Plates, etc. | ≥4 Years | HRC≥52 | ≥40 |

Middle Carbon Alloy Steel | ≥3 Years | HRC≥50 | ≥30 | |

Middle Chromium Alloy Steel | ≥2 Years | HRC≥48 | ≥20 | |

Low Chromium Alloy Steel | ≥1.5 Years | HRC≥45 | ≥40 | |

Low Carbon High Chromium Alloy Steel | Mining Wet Grinding Liners Plate, Aside Liners, Grid Place Etc Big Raw Material Mill,Etc | ≥1 Years | HRC≥46 | ≥50 |

≥3 Years | ||||

High Manganese Steel (Mn13) | Mining Wet Grinding Liners Plate, Aside Liners, Grid Place Etc | ≥8 Months | HB≥200 | ≥147 |

High Manganese Alloy Steel (Mn13Cr2) | Crusher Impact Plate, Jaw Crusher Plates | ≥1 Years | HB≥220 | ≥120 |

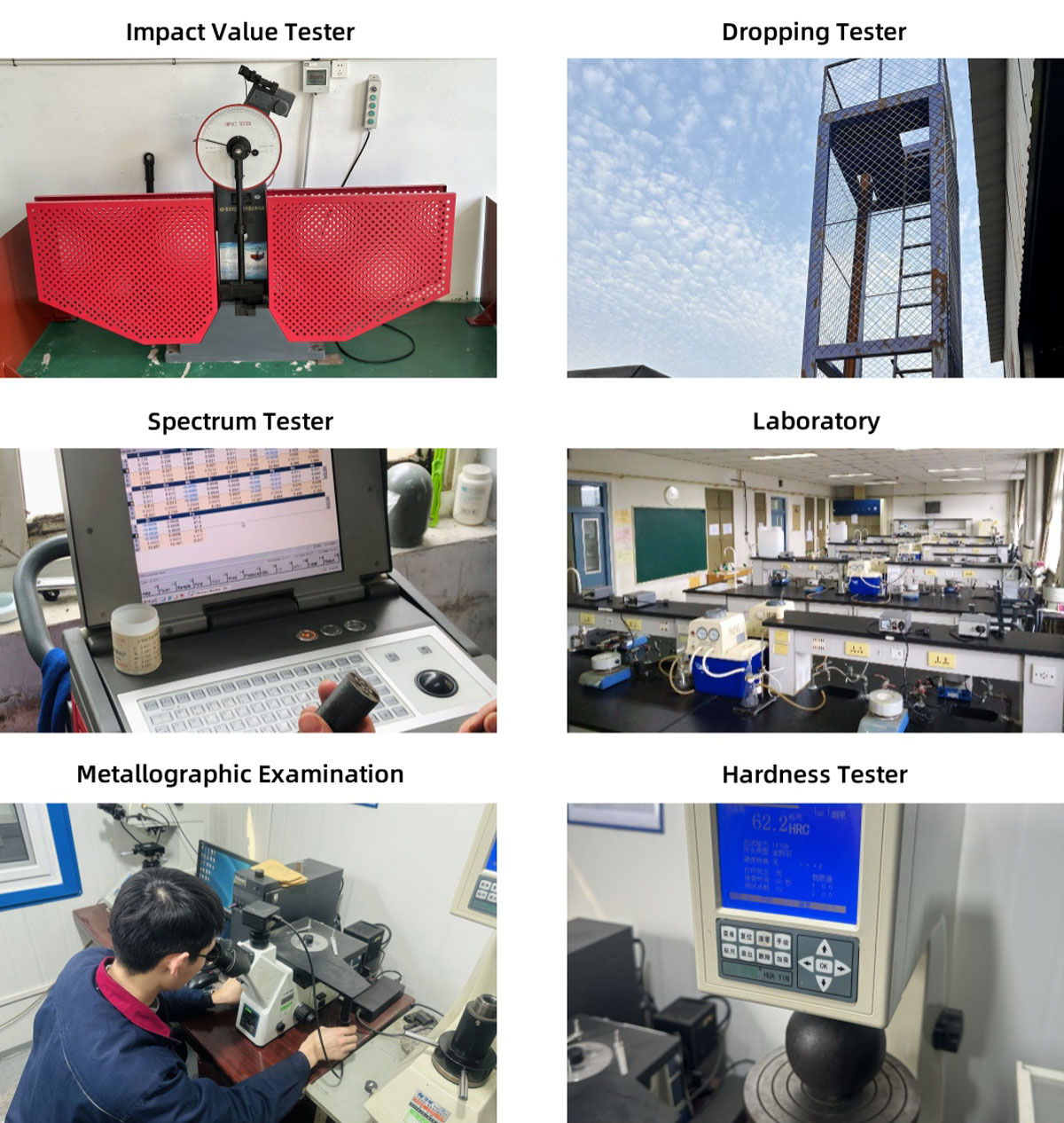

Quality Control Technology and Equipment

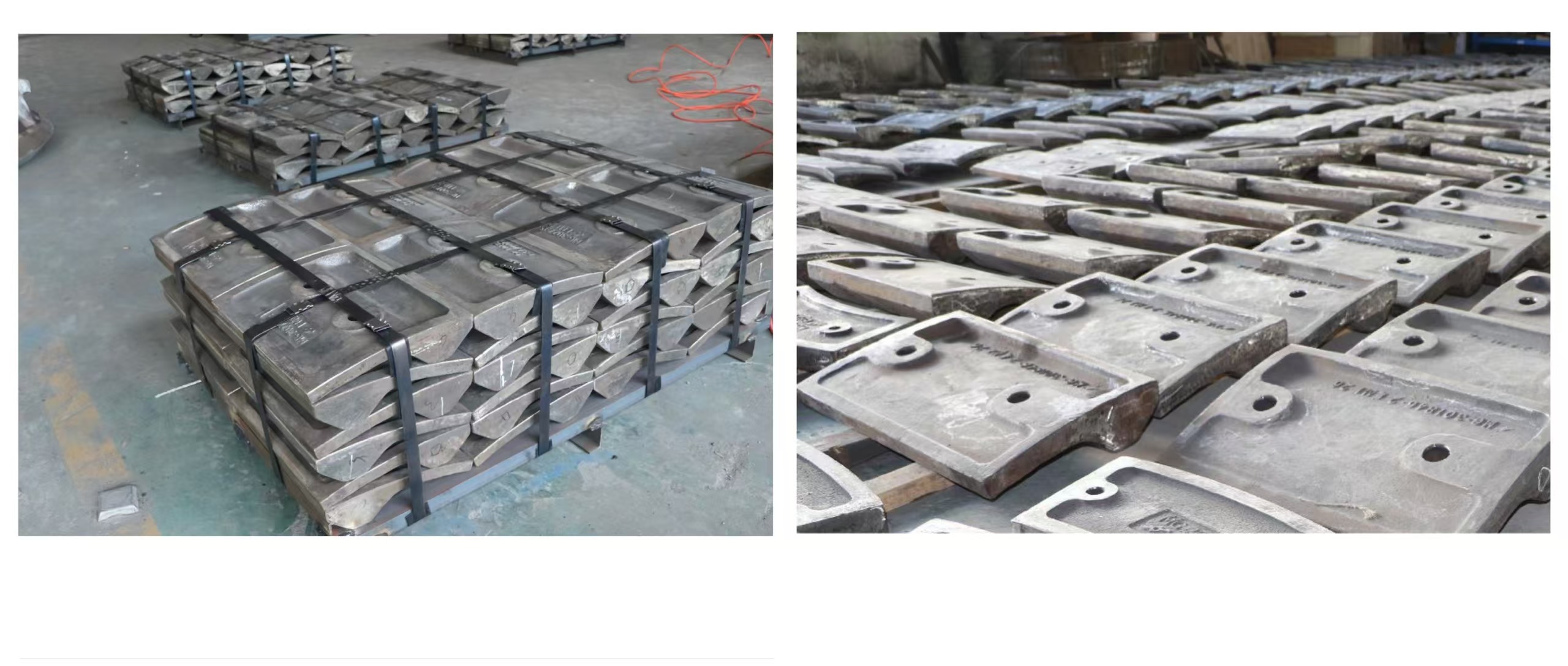

Plants and Production Equipment

Exhibitions

Why choose us

Recognizing the diverse needs of milling operations, the SAG Mill Liners can be customized in terms of material composition, profile, and thickness. Whether dealing with abrasive ores or varying mill sizes, these liners can be tailored to meet specific operational demands. This adaptability ensures optimal performance and longevity, making them suitable for a wide range of mining and industrial applications.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible