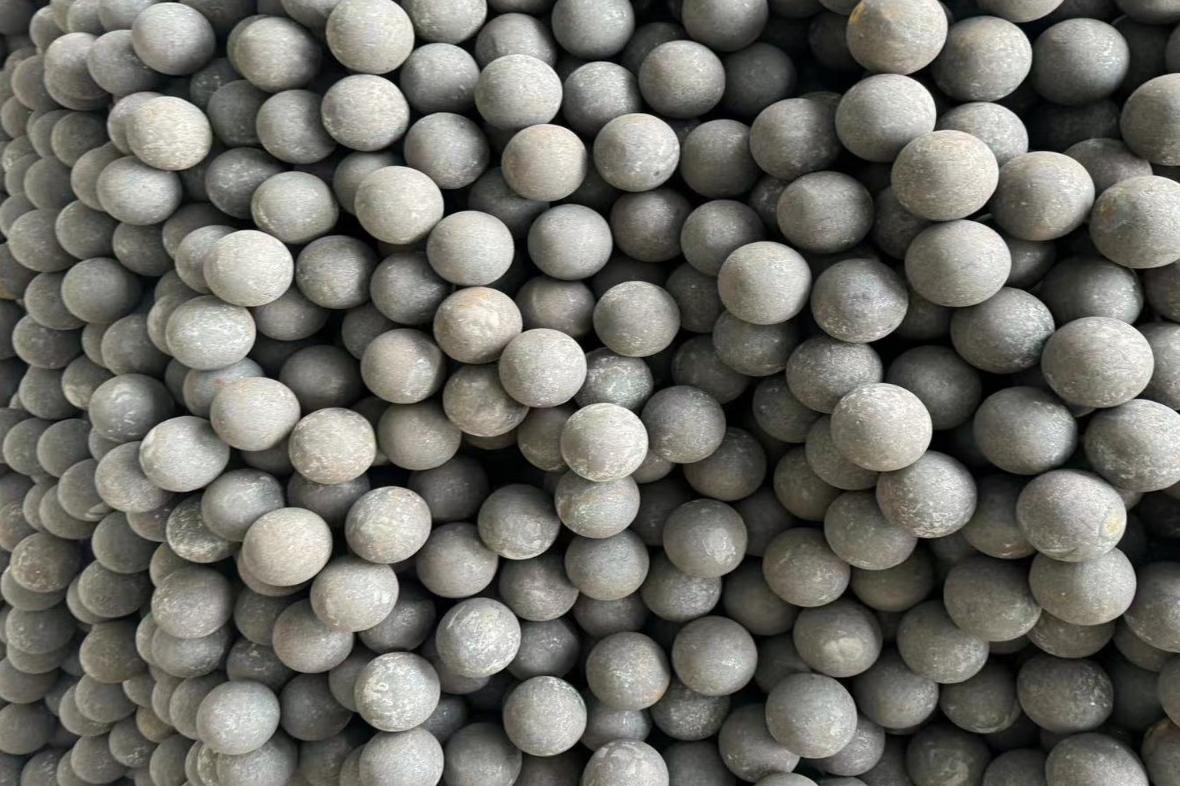

SAG Mill Grinding Ball

The SAG Mill Grinding Ball is designed to withstand the extreme conditions of semi-autogenous grinding (SAG) mills. These balls are crafted from high-quality materials that offer exceptional wear resistance, making them ideal for grinding hard and abrasive ores. The durable construction ensures long-lasting performance, reducing the frequency of replacements and minimizing downtime in industrial operations. With their superior toughness, these grinding balls are a reliable solution for SAG mills operating under high-impact grinding conditions.

Introduction of the product

The SAG Mill Grinding Ball is engineered to enhance the efficiency of the grinding process. Its uniform size, shape, and hardness contribute to a smooth grinding action, which ensures a more efficient reduction of ore particles. This optimized performance improves throughput and reduces energy consumption, making the grinding process more cost-effective. Whether working with copper, gold, or other hard ores, these balls deliver consistent results, maximizing both the efficiency and productivity of SAG mills.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·SAG mills | ·Power stations |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

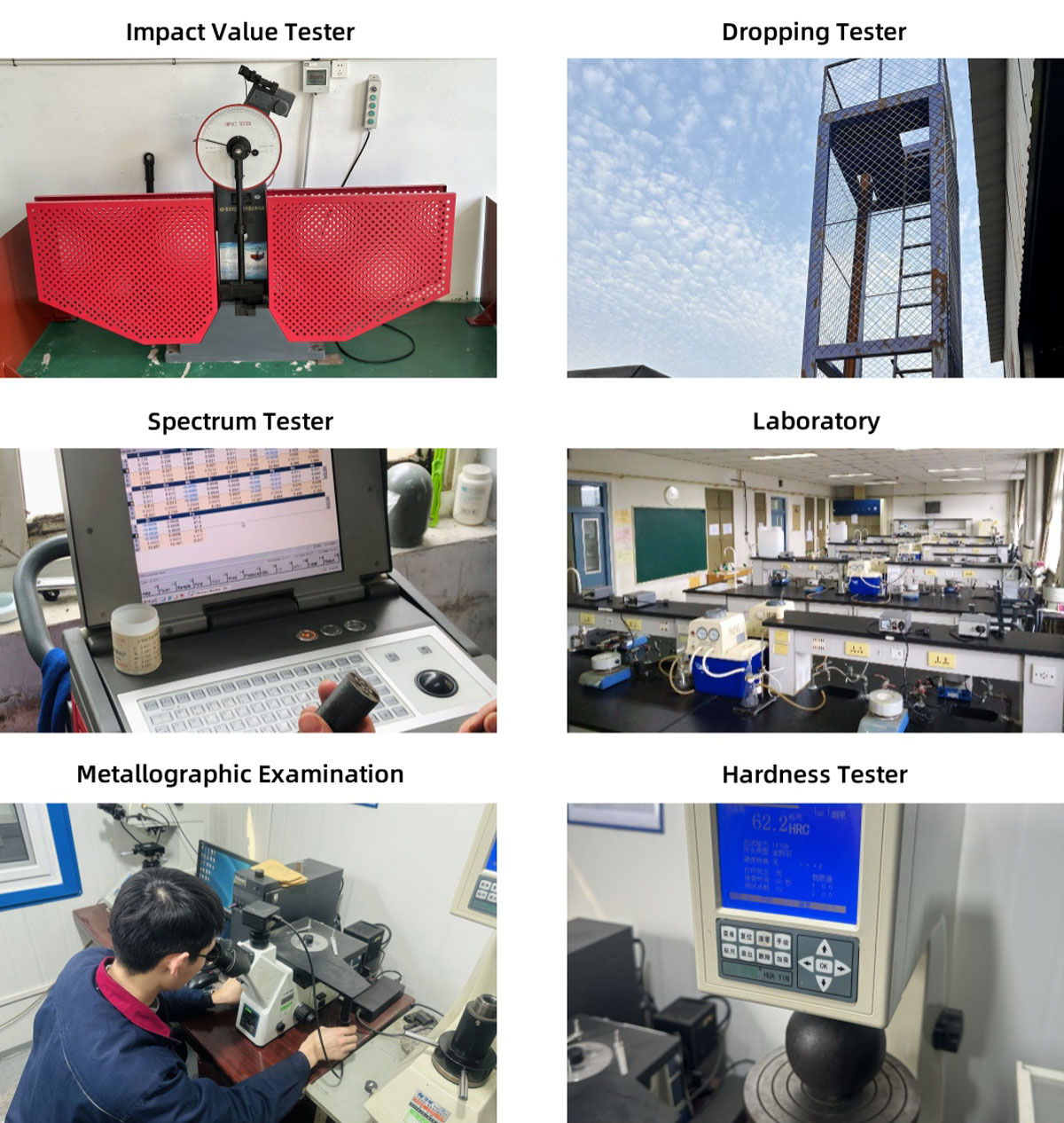

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

To meet the diverse needs of SAG milling applications, the SAG Mill Grinding Ball can be customized in terms of size, hardness, and material composition. This allows for tailored solutions depending on the specific requirements of the grinding process and the types of ores being processed. Customization ensures that these grinding balls provide the best possible performance, whether in terms of wear resistance, grinding efficiency, or overall longevity, making them an invaluable asset for mining and other heavy-duty grinding applications.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible