Forged Grinding Cylpebs

The Forged grinding balls are one of the most widely used grinding media. It was added in different types of mills, to break, crash, impact and abrase the minerals ores and other materials in small pieces and even powders. We offer grinding balls in different sizes, with various chemical components and hardness to fulfil different types of mills and ores.

Introduction of the product

Forged grinding balls are among the most commonly used grinding media. They are incorporated into various types of mills to crush, break, impact, and grind minerals, ores, and other materials into smaller pieces or even powders. We provide grinding balls in a range of sizes, with different chemical compositions and hardness levels to meet the specific needs of various mills and ores.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | ||||||

Diameter × Length (mm) | Surface Hardness(HRC) | Diameter Tolerance (mm) | Length Tolerance (mm) | Impact Value(J/cm²) | Breakage Rate (%) | Drop Test (times) |

Φ20×25 | 60-66 | +1.2 -1.0 | +1.5 -1.5 | ≥12 | ≤1 | >15000 |

Φ25×30 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ30×35 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ30×40 | +1.5 -1.5 | +2.0 -2.0 | ||||

Φ35×40 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ35×45 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ40×50 | +2.0 -2.0 | +2.5 -2.5 | ||||

Φ45×55 | +2.0 -2.0 | +2.5 -2.5 | ||||

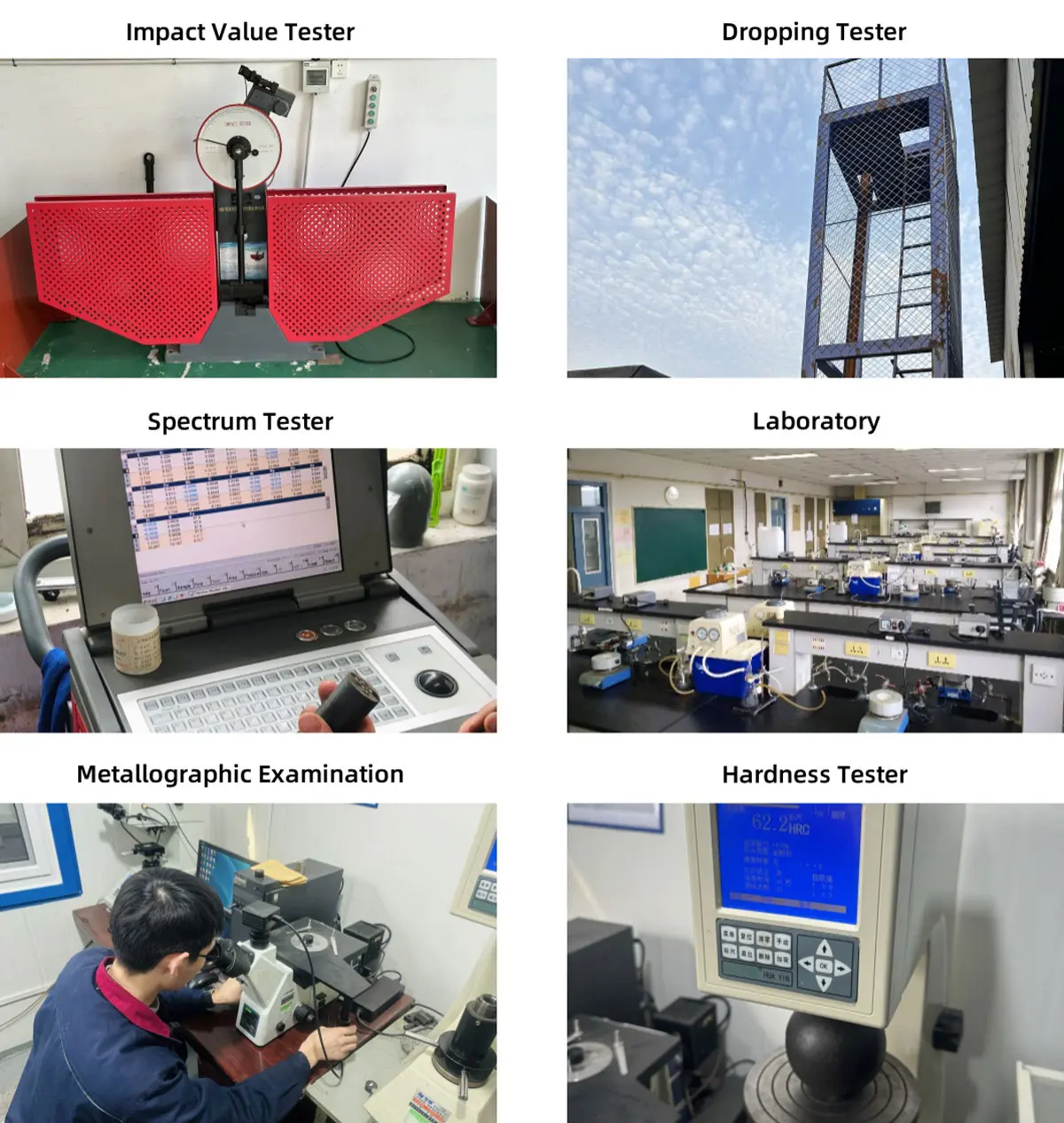

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

Stringent quality assurance protocols are in place.

A wide variety of products is available.

High production capacity and abundant inventory (150,000 tons per year, with over 3,000 tons in stock).

Laboratory testing certified by SGS and Bureau Veritas.

Decades of experience, with over 20 years in the industry and exports to more than 30 countries.

An expert team and cutting-edge R&D capabilities (100+ professionals, 10+ offices, and over 50 patents).

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible