Grinding Bars For Mining

Grinding Bars for Mining are essential for efficient and reliable grinding in mineral processing. Designed for use in rod mills, these bars are made from high-quality materials to withstand the harsh conditions of mining operations. With their superior wear resistance and uniform hardness, Grinding Bars for Mining provide consistent performance and long service life, ensuring optimal grinding efficiency and minimizing downtime in the milling process.

Introduction of the product

Understanding that each mining operation has its own unique requirements, we offer customizable Grinding Bars for Mining to meet specific needs. Whether you require different lengths, diameters, or material compositions, we can tailor our bars to optimize the grinding process in your mills. This flexibility ensures that you can achieve the highest level of performance and efficiency in your mining operations.

Application in grinding machines and areas

Machines | Industries |

·Rod mills | ·Mining industry |

·Bar mills | ·Power stations |

·Cement industry | |

·Quartz/Silica sand factory | |

·Coal Chemical Industry | |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||||

Steel Specification | Impact Value (J/cm²) | Surface Hardness (HRC) | Diameter (mm) | Length (mm) | Broken Rod Rate (%) | Diameter Tolerance (mm) | Length Tolerance (mm) |

40Cr | ≥12 | 45-60 | 25-140 | 1500-6000 | ≤1 | ±1.5 | ±20 |

42CrMo | |||||||

#45/C45 | |||||||

60Mn | |||||||

65Mn | |||||||

B2 | |||||||

B3 | |||||||

BU | |||||||

BL | |||||||

BG | |||||||

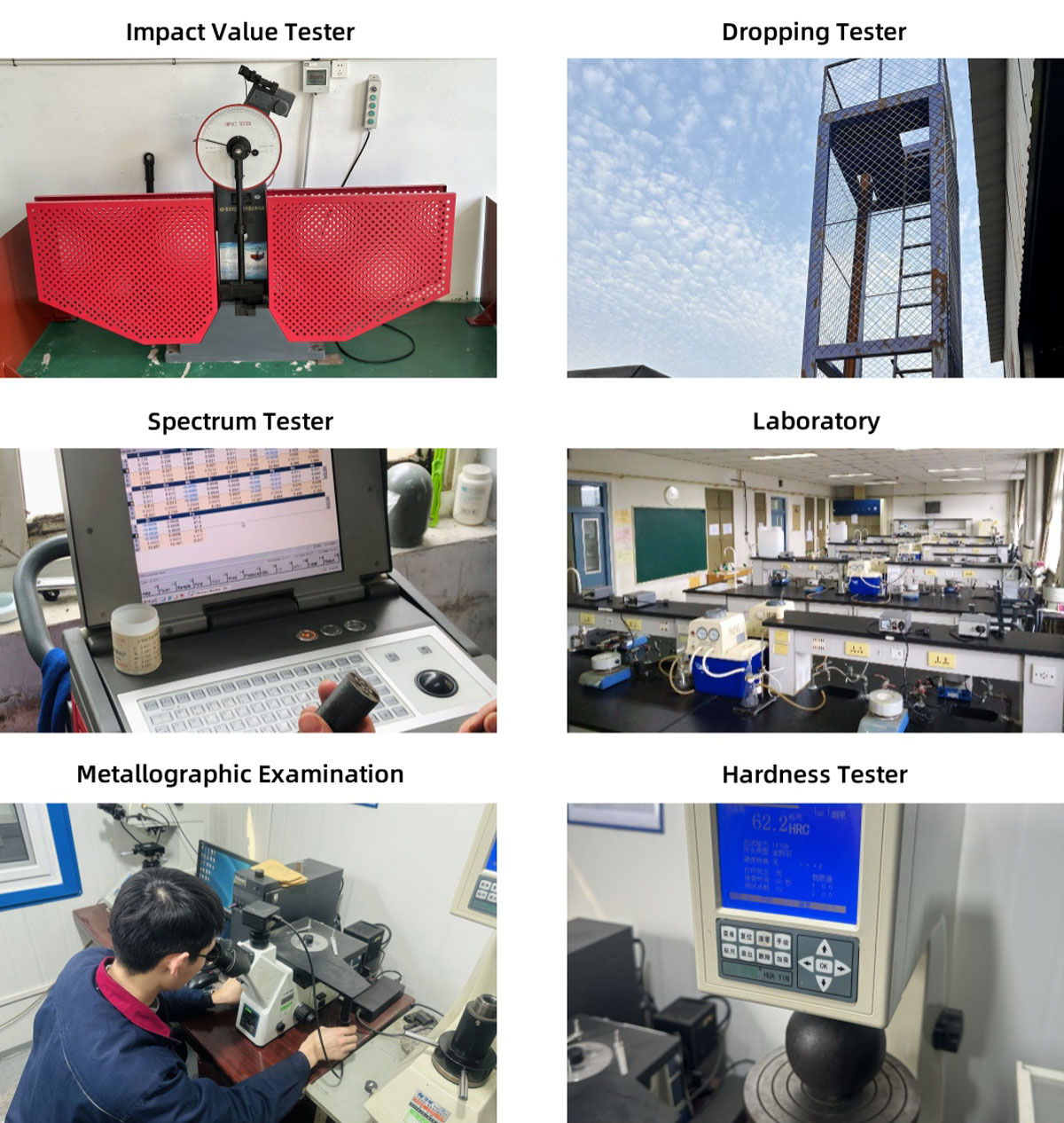

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

One of the key advantages of our Grinding Bars for Mining is their excellent durability and low breakage rate. Manufactured with advanced heat treatment processes, these grinding bars offer high impact resistance and are designed to minimize fractures during the grinding process. This significantly reduces the frequency of replacements and ensures a more continuous, cost-effective mining operation.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible