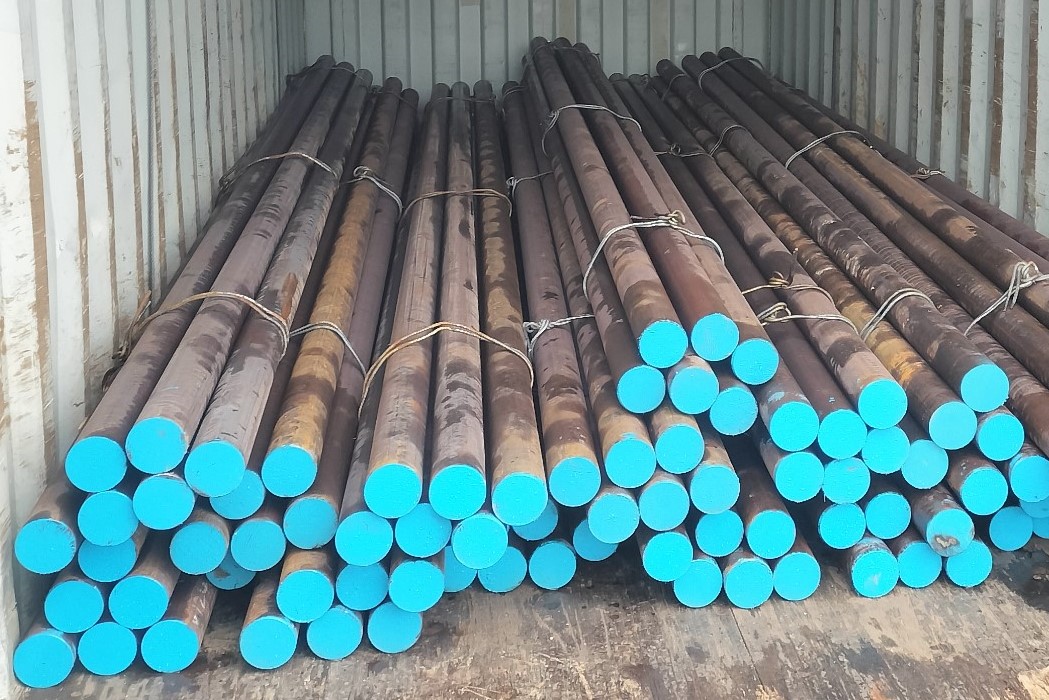

Grinding Bar For Mining

Grinding Bar for Mining: Reliable Performance for Mining Operations

Grinding Bar for Mining is a key component in the grinding process, specifically designed for use in rod mills. Made from high-quality materials, these grinding bars offer superior wear resistance, providing long-lasting durability in harsh mining environments. With their consistent hardness and strength, Grinding Bar for Mining ensures smooth and efficient grinding operations, contributing to higher productivity and reduced downtime.

Introduction of the product

One of the main advantages of our Grinding Bar for Mining is its exceptional durability. Thanks to advanced manufacturing techniques and heat treatment processes, these bars offer increased impact resistance and wear resistance. This durability results in reduced wear and tear, extending the lifespan of the bars and reducing the need for frequent replacements, which helps optimize operational costs and minimize downtime.

Application in grinding machines and areas

Machines | Industries |

·Rod mills | ·Mining industry |

·Bar mills | ·Power stations |

·Cement industry | |

·Quartz/Silica sand factory | |

·Coal Chemical Industry | |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||||

Steel Specification | Impact Value (J/cm²) | Surface Hardness (HRC) | Diameter (mm) | Length (mm) | Broken Rod Rate (%) | Diameter Tolerance (mm) | Length Tolerance (mm) |

40Cr | ≥12 | 45-60 | 25-140 | 1500-6000 | ≤1 | ±1.5 | ±20 |

42CrMo | |||||||

#45/C45 | |||||||

60Mn | |||||||

65Mn | |||||||

B2 | |||||||

B3 | |||||||

BU | |||||||

BL | |||||||

BG | |||||||

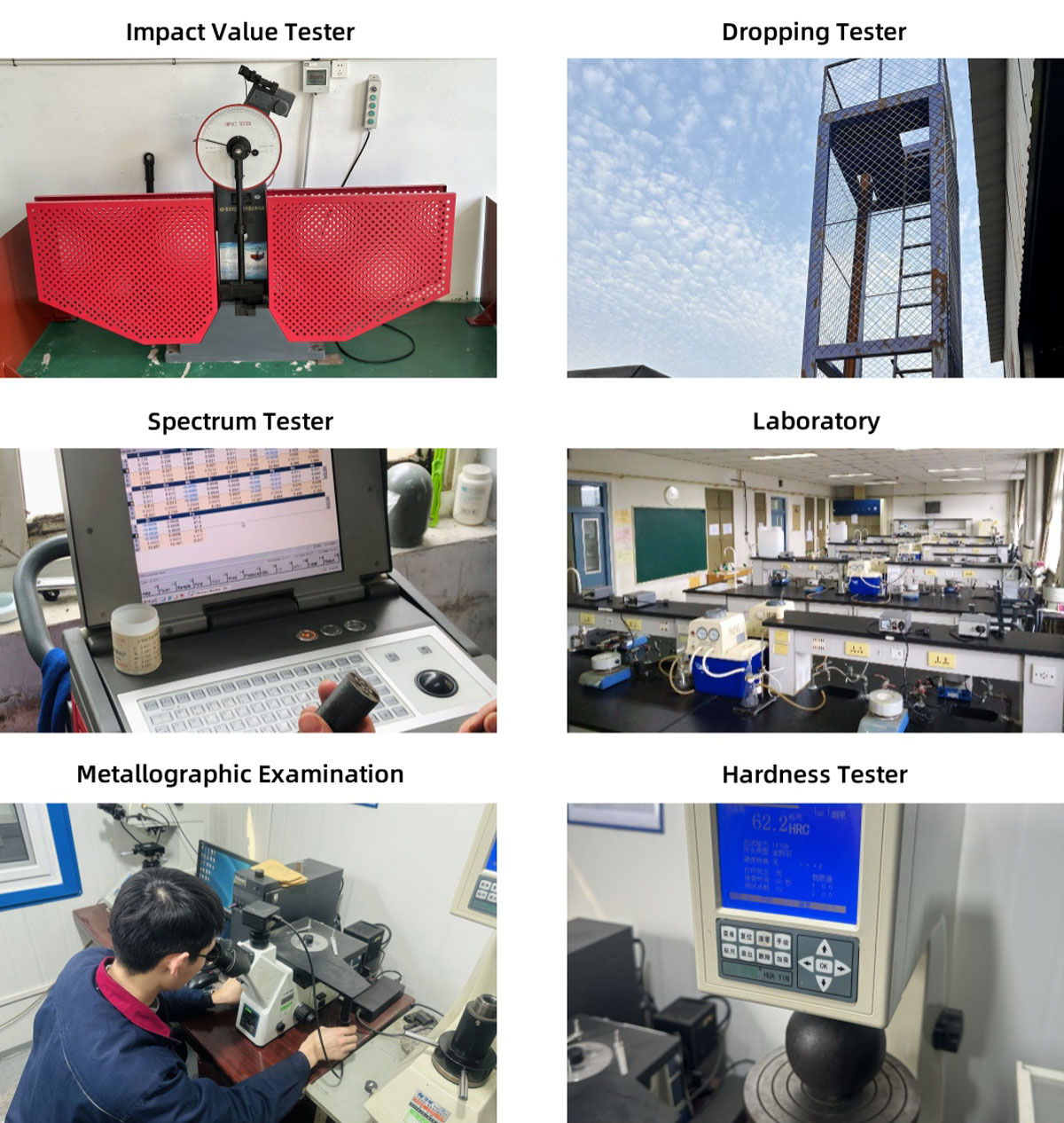

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

To meet the diverse needs of the mining industry, we offer fully customizable Grinding Bar for Mining. Whether it's adjusting the length, diameter, or material composition, we can tailor the grinding bars to suit your specific grinding requirements. This flexibility allows you to optimize your milling process and achieve the best results in your mining operations, while enhancing both efficiency and cost-effectiveness.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible